what is sheet metal workshop WORKSHOP REPORT sheet metalworking - Free download as Word Doc (.doc / .docx), PDF File (.pdf), Text File (.txt) or read online for free. The document is a workshop report for a course on technology and handwork practice. It . $27.99

0 · various sheet metal processes

1 · sheet metal workshop pdf

2 · sheet metal operations with diagrams

3 · sheet metal fabricator

4 · sheet metal diagram fabrication

5 · sheet metal courses near me

6 · shearing operation in sheet metal

7 · custom metal sheet fabrication

Here we outline the two most common ways to meet that requirement - the loop-in wiring and the radial wiring (also referred to as 'junction box) installations. Picture 1 shows the basic principle of wiring a loop-in lighting system (the most modern/common).

A sheet metal worker specializes in working with thin metal sheets to fabricate, install, and maintain various products and systems. They use blueprints and technical drawings to measure, cut, shape, and join metal sheets using .The manufacturing & design guide. Learn how to effectively design sheet metal parts. This guide starts with the basics and moves toward design best practices and advice on material . Working in the metal fabrication industry can be dangerous without the correct safety procedures. Learn how to improve safety for your employees today. Give us a call 610-921-1119WORKSHOP REPORT sheet metalworking - Free download as Word Doc (.doc / .docx), PDF File (.pdf), Text File (.txt) or read online for free. The document is a workshop report for a course on technology and handwork practice. It .

Pretty much exclusively deals with the use of hand tools, rather than the kind of machinery one would find in a professional sheet metal shop, and that was precisely what I wanted. With the understanding that this is definitely .Millennium Buildings lets you customize your metal workshop in many ways. You can make any tweaks big or small that you need to personalize your workshop. Our metal workshops are available in all sizes. You can start by selecting the size that works for you. Further, you can request to make custom changes in workshop’s roof, walls, doors, etc.

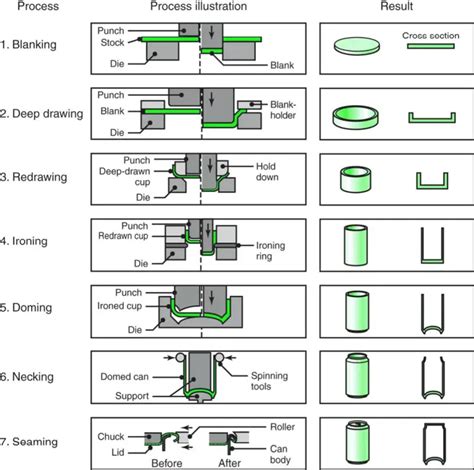

In the manufacturing industry, the sheet metal process is common, and sheet metal parts are used in many different industries, including consumer products, appliances, aircraft, and the automotive and aerospace sectors. Sheet Metal Operations. Following are the 9 different types of sheet metal operations: Shearing Operations; Blanking OperationsSheet metal is available in flat pieces or coiled strips. The coils are formed by running a continuous sheet of metal through a roll slitter. In most of the world, sheet metal thickness is consistently specified in millimeters. In the U.S., the thickness of sheet metal is commonly specified by a traditional, non-linear measure known as its gauge.Top 10 Best Metal Workshops in San Diego, CA - November 2023 - Yelp - San Diego Mobile Welding, Art on 30th, VetPowered, Benchmark Custom Welding, Lovejoy Creations, Kitchens For Good, South Bay Welding, Sparks Gallery, Mariachi Real de San Diego, FEMX QuartersSheet metal is metal formed by an industrial process into thin, flat pieces. It is one of the fundamental forms used in metalworking and it can be cut and bent into a variety of shapes. Countless everyday objects are constructed with sheet metal. Thicknesses can vary significantly; extremely thin thicknesses are considered foil or leaf, and pieces thicker than 6 mm (0.25 in) .

Study with Quizlet and memorize flashcards containing terms like True or false: The sheet metal shop is very important for every engineering concern., what does sheet metal workshop deal with?, he laying out of pattern and cutting of metal sheet to correct sizes and shapes entirely depends upon... Therefore, and more.

various sheet metal processes

Sheet metal is simply metal formed into thin and flat pieces. It is one of the fundamental forms used in metalworking, and can be cut and bent into a variety of different shapes. Thicknesses can vary significantly, although extremely thin thicknesses are considered foil or leaf, and pieces thicker than 6 mm (0.25 in) are considered plate. . I will show you how I made Sheet Metal Bender Machine in my Meanwhile in the Garage workshop, This sheet metal bender is constructed from I-beam, pipe, bearings, steel plate, threaded rod, nuts . A metal nibbler is a sheet metal cutting tool that quickly reciprocates a punch to cut, or ‘nibble’ away at, very small pieces of metal. This continuous motion gives the tool the ability to cut through a wide range of sheet materials including steel, aluminum, stainless steel, copper, fiberglass, plastic, and soft materials such as paper or .It is a very common metal product that has plenty of applications, and fabrication usually happens within the factory. Sheet metal is a relatively thin material, which means compared to other products, it can be more prone to damages and imperfections. But any good metalworker should know how to check sheet metal quality.

The book includes 20 projects designed by Mary, many of which combine sheet metal, metal clay, and wire.” - Bead&Button “ Mixed Metal Jewelry Workshop combines metal clay with traditional metal forms including sheet metal, wire, and other embellishments in 20 jewelry projects. Also included are chapters on materials, tools, techniques and a .

sheet metal | Mechanical Engineering Workshop

2. Technical requirements of sheet metal workshop - Electrical. Sheet metal workshop has a large load and a lot of equipment. The power supply of the workshop is generally designed according to the cable power supply. In some places, the busway can be reserved. - Gas. Low pressure compressed air is generally used in sheet metal workshop.

sheet metal workshop pdf

sheet metal operations with diagrams

sheet metal fabricator

Sheet metal fabrication is a highly competitive industry driven by the increasing demand for custom-made metal products across various sectors. From automotive and aerospace to construction and electronics, the need for . The laser drilling in the sheet metal workshop generally uses a pulsed laser, which has higher energy density and shorter time. It can process 1μm small holes, especially suitable for processing small holes with a certain angle and thin material, and is also suitable for processing strength. Deep and small holes and tiny holes on parts with .

Workshop Technology Viva ,Objective questions with Answers For Mechanical Students . Currently, he is working in the sheet metal industry as a designer. Additionally, he has interested in Product Design, Animation, and Project design. He also likes to write articles related to the mechanical engineering field and tries to motivate other .

Tin Smithy-WorkShop Manual - Free download as PDF File (.pdf), Text File (.txt) or read online for free. This document provides instructions for three sheet metal projects: a trapezoidal tray, a T-joint, and a funnel. It includes the tools needed, materials required, step-by-step procedures, and safety precautions for completing each project.

The mixed flow production line of various parts in the sheet metal workshop is optimized and researched, and the optimized results are finally obtained. After studying this problem with the multi-objective optimization mathematical model and genetic algorithm proposed in this paper, the production cycle is 26.5 hours, and the assembly line .How does sheet metal fabrication work? There are several different ways to shape sheet metal, but they all boil down to two broad categories: sheet metal can either be cut or formed. As there are many different ways of cutting and forming sheet metal, many specific tooling types are needed which can drive up costs.A dust pan will be constructed out of sheet metal by using tools and equipment to make proper bends in the metal and fastened by various means. Materials: 26 ga. Galvanized sheet metal . 3/8” black pipe . ¼”x4.5” carriage bolt . Self locking ¼” NC nut . Tools: Snips . Sheet metal sheer . Sheet metal brake . Finger Brake . Pop rivet .

The sheet metal production process powers the Australian industry– almost every kind of producer relies, in some way, on parts, specialised components, structures, or devices that are a direct outcome of sheet metal fabrication.. From big commercial structures and supports to the most sensitive digital assemblies, sheet metal plays a key role in diverse industries. As the application of sheet metal continues to expand, the design of sheet metal parts has become a critical aspect of product development. Mechanical engineers must be well-versed in the design of sheet metal components to ensure that the parts meet the necessary functional and aesthetic requirements while keeping the stamping die production .ANS:- Workshop is the center of learning about engineering Materials, manufacturing practices, equipments, tools and safety precaution to be observed in manufacturing . Sheet metal (vi) Electric arc and gas welding (vii) Machine shop Q.4 Which are Special shops? ANS:- (i) Electrical wiring, soldering,& electronic (ii) Painting .

Safety Tips When Fabricating Metal Components/ Instruments. The following steps can be employed when using metal fabrication tools: Proper Training: This is a very important step in any metal fabrication project.A detailed training session regarding the equipment, occupational hazards, and working conditions should be given to the personnel.

sheet metal emboss design guidelines

sheet metal ductwork fabrication fresno ca

$19.79

what is sheet metal workshop|sheet metal workshop pdf