sheet metal process name Sheet metal fabrication is a versatile approach that begins with the selection of a flat metal sheet, typically steel, aluminum, or stainless steel, and transforms it into the desired component through various processes. Correct fill capacity: The junction box should be large enough to contain the wires. .

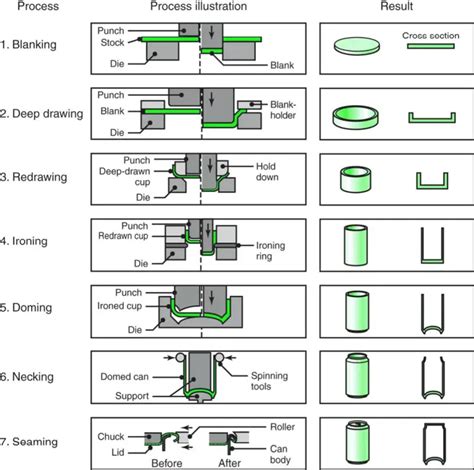

0 · various sheet metal processes

1 · types of sheet metal process

2 · types of sheet metal fabrication

3 · sheet metal working process pdf

4 · sheet metal process pdf

5 · sheet metal process in manufacturing

6 · sheet metal operations with diagrams

7 · sheet metal fabrication pdf

Electrical service to the dishwasher comes through the floor in the center of the dishwasher cabinet opening. The old dishwasher had an electrical box integrated into the bottom of the dishwasher, and the electrical cable reached this box.

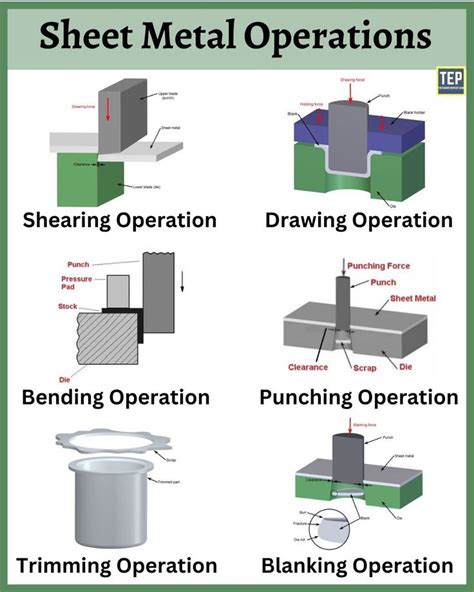

However, there are two categories of sheet metal operations: cutting and forming. Under the two subcategories, there are nine other processes that make up sheet metal operations as a whole. 1. Shearing. Shearing is .Sheet metal fabrication is a versatile approach that begins with the selection of a flat metal sheet, typically steel, aluminum, or stainless steel, and transforms it into the desired component through various processes.

Table of Contents. 9 Steps in Sheet Metal Fabrication Process. Step #1: The Design Phase. Step #2: Material Selection. Step #3: Cutting the Metal. Step #4: Forming and Shaping. Step #5: .Sheet metal manufacturing is the process of creating sheet metal parts by cutting, bending, and forming thin metal sheets into specific shapes and sizes. The process typically uses coating, cutting, bending, and assembly techniques.

The process involves the sheet metal being placed over a die, then pressed with a punch into an open cavity, causing the material to undergo plastic deformation. The process allows for precisely made complex shapes .28.01.2020 by Andreas Velling. What Is Sheet Metal Fabrication? Table of Contents hide. I Updated 16 August 2023. II Types of Metal Fabrication Processes. III Advantages of Sheet Metal. IV Sheet Metal Applications. . Home. Blog. Sheet Metal Fabrication: An Ultimate Guide on Manufacturing Processes and Design. Ultimate Guide to Sheet Metal Fabrication. Unlock the full potential of sheet metal fabrication with our comprehensive .1. Cutting is a sheet metal forming process where the main objective is to sever the metal by removing material. It is a crucial procedure in sheet metal manufacturing as it allows for the shaping and sizing of the metal to specific .

Sheet metal forming is a process used in many industries to make metal parts from thin metal sheets. It’s actually one of Xometry's most popular manufacturing methods. . The process is used to (as the name suggests) .

Sheet metal fabrication is the process of transforming flat metal sheets into products. Metal fabrication inclues cutting, punching, bending, etc. . As the name suggests, it is rolled at room temperature. Cold rolled steel is .

Good sheet metal design goes beyond basic guidelines and considers the type of sheet metal fabrication process, material, finish, fastening, and tailors all these factors to the specific function. Here are some useful resources on sheet . Accuracy is the name of the game here, and the shearing sheet metal process helps to achieve that optimally. Many manufacturers also love the shearing metal process because it doesn’t take much heat or produce much waste. Compared to a lot of other metal forming processes, the sheet metal forming shearing process is known for being especially . The sheet metal blanking process is a fundamental aspect of the manufacturing industry that converts flat metal sheets into specific, predefined shapes for a variety of uses. This method is known for its efficiency and is especially advantageous for high-volume production. Let’s take a closer look at how sheet metal blanking operates.Name 2 things that happen as you increase the clearance? . Process where sheet metal is clamped around its edges and is stretch over a die or form block. Used for large parts such as aircraft-wing skin panels and automobile door panels. roll forming. bulging. stretch forming.

Sheet-Metal Forming Processes Process Roll forming Stretch forming Drawing Stamping Rubber-pad forming Spinning Superplastic forming Peen forming Explosive forming Magnetic-pulse forming Characteristics Long parts with constant complex cross-sections; good surface finish; high production rates; high tooling costs. It’s a process that cuts sheet metal into specific shapes and sizes. This technique requires applying heavy force to the metal, resulting in a clean, straight fracture. . Despite its simple name, metal fabrication has several stages that result in a high-quality product that follows specifications. One of those stages is sheet metal forming .Sheet Metal Forming; Process Type: Plastic deformation of a bulk material: Plastic deformation of thin sheets: Material Thickness: . Sheet metal forming, as the name suggests, focuses on shaping thin sheets of metal into various products. It is commonly used in industries such as automotive, aerospace, and construction, where lightweight and .Sheet metal blanking is a foundational fabrication technique that enables precise cutting and optimized material usage. An efficient blanking process directly contributes to product quality and cost-effectiveness. In this guide, we’ll discover a detailed breakdown of the 9 steps involved in sheet metal blanking.

A sheet metal stamping process is a metalworking process carried out at room temperature wherein parts are both cut and shaped from a parent metal strip or. . as the name suggests, is a drawing operation in which the article is no deeper than half its diameter. Title block with part name, number, material specification, and other relevant information; Scale; Dimensions and annotations; . Bending is a fundamental sheet metal forming process that transforms 2D flat parts into 3D components with precise angles and contours.Metal stamping is an incredibly versatile and efficient manufacturing process that takes flat metal sheets or coils and transforms them into precisely shaped and intricate parts. By utilizing force, pressure, and specialized tooling, components with diverse forms — including bends, curves, cutouts, and embossing, are possible.

Sheet metal processing covers the entire process from design to finished product, involving many key links such as material selection, process determination, and precision control. This article will deeply explore the common process types and significant advantages of sheet metal processing, helping users make more informed choices when . Sheet Metal Fabrication has become the need of the 21st century as every industry you name, whether it is aircraft, railway, plumbing, manufacturing, or any other requires sheet metal to build products that can .The sheet metal stamping process is a strategic advantage that can set your business apart. Precision, efficiency, and innovation are at its core, driving the production of high-quality components. Precision, efficiency, and innovation are at its core, driving the production of high-quality components.

Study with Quizlet and memorize flashcards containing terms like Sheet metal working includes both forming and cutting operations. true or false, most sheet metal working operations are performed as a)cold working b)hot working . The stamping process starts with a coil of sheet metal. Each blank may be cut-to-length, or blanked, after the coil is decoiled—either at a steel service center or inhouse using a blanking line. Some metal forming companies dub the blanking process OP05, and others OP10. For example, when processing parts that include an offline blank die .

various sheet metal processes

types of sheet metal process

Bending is a metal forming process in which a force is applied to a piece of sheet metal, causing it to bend at an angle and form the desired shape. 7. Two common bending methods are: V-Bending Edge bending V-Bending: The sheet metal blank is bent between a Vshaped punch and die.

In this process, sheet metal fabricators place a blank, flat workpiece in a stamping press. The press contains a die with the desired shape. When the stamping force is applied, the metal is deformed into the shape of the die. . As the name implies, hardening increases the workpiece's hardness and resistance to wear, abrasion, and deformation . In this metal-forming process, a sheet of metal is passed through perforating scissors where it is cut and stretched into a pattern. Usually, a diamond-shaped mesh is preferred as it has a structural advantage over other shapes. This forming process is commonly used for manufacturing fences, catwalks, platforms, grating, etc.

types of sheet metal fabrication

In this article we will discuss about the sheet metal manufacturing process and its operation types. Introduction to Sheet Metal Work: Most of the sheet metal work is done on presses where a die and punch or other formed tools are required. In press work large force is applied on thin sheet metals to give the required shape or to cut it in to the desired shape. Press work is highly .

sheet metal working process pdf

5. Sheet Metal Processing The raw material for sheet metal manufacturing processes is the output of the rolling process. Typically, sheets of metal are sold as flat, rectangular sheets of standard size. If the sheets are thin and very long, they may be in the form of rolls. Therefore the first step in any sheet metal process is to cut the correct shape and . Bending sheet metal is another important phase in the production process. Bending the metal sheets is what this process is all about, as the name suggests. Sheet metal is bent by metal fabricators utilizing a variety of machinery and tools, including press brakes, rolling equipment, and other machinery. The material selection process is one of the most challenging parts of the sheet metal fabrication process. An inaccurate choice could lead to a loss of but also of valuable time. This article is aimed at simplifying the process of selecting suitable sheet cutting materials. Table of Contents. Aluminium Alloys; Stainless Steel Materials . Typical Sheet Metal Process Selection. Laser, waterjet, or plasma techniques are normally used in precision metal fabrication. These techniques reduce material wastage and provide the accurate dimensions desired in any project. . Save my name, email, and website in this browser for the next time I comment. Submit Comment. ← Prev:Gear .

sheet metal company for bending process. They have used Ishikawa diagram for root cause analysis of sheet metal bending process problems and implemented FMEA procedure successfully. M.Dudek-Burlikowska[3] have suggested integration of quality management and quality control system for success of companies.

sheet metal process pdf

10-gauge mild steel, designed to box from ahead of the front crossmember to about the middle of the frame. Plate is 60-1/2" long. Order two of these boxing plates to box the front half of a pair of rails.

sheet metal process name|sheet metal fabrication pdf