electrical box is ressessed behind drywall needs to be flush My issue is that I need to install new work boxes so that they extend 1 1/4" beyond the stud. This way, when my second layer of 5/8" drywall goes up, it will be flush. I don't have enough depth with the boxes I am using to go out 1 1/4", so I am wondering if I can extend it 1 1/8" instead. You could bolt together a frame from L75x75x5mm steel angle that would drill easier (on the bench no less), do the same job, and pretty much eliminate drilling your cast base. That size angle would most likely support almost any wood lathe and some lighter metal lathes.

0 · should electrical boxes be flushed

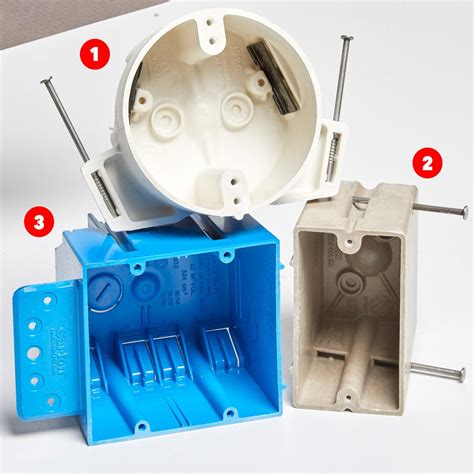

1 · sheetrock electrical boxes

2 · electrical box recess depth

3 · electrical box flush with drywall

4 · drywall for electrical boxes

5 · boxes recessed too deep

6 · box recessed too deep diy

7 · adjustable electrical box depth

$85.00

My issue is that I need to install new work boxes so that they extend 1 1/4" beyond the stud. This way, when my second layer of 5/8" drywall goes up, it will be flush. I don't have enough depth with the boxes I am using to go out 1 1/4", so I am wondering if I can extend it 1 1/8" instead.The simple answer is that, if the box is flush with your mounting surface, it might be . boxes should be flush with outside of drywall, however i believe you're allowed 1/4 if they are non-metallic. You don't want the box to stick out..but it's ok for it to be recessed a bit.. When you install the recept, the .

The box/mudring doesn't need to be flush on a non combustible wall finish (like drywall), it can be recessed up to 1/4 inch. This 1/8 inch gap rule applies to how big of a gap is . The simple answer is that, if the box is flush with your mounting surface, it might be compliant as-is after tiling. If not (i.e. your tile is over 1/4"), you can make it compliant with an . No gap is allowed between the front of a panel box and the wall surface that the dead front of a recessed panel will sit against in a regular wood stud (combustible) wall structure, but a 1/4” gap is acceptable in a .

Gaps around boxes that are recessed in noncombustible surfaces (such as plaster, drywall, or plasterboard) must be repaired so there will be no gap greater than 1⁄8 in. at the edge of the box (Fig. 2). The NEC 314.29 prohibits covering up boxes such that you'd need to remove "part of the building" to access the wires inside. The drywall is considered "part of the building." You .

They fold over on themselves and you can make a stack however long you need to get the outlet flush with the wall. Rip off the excess and save what's left for later. You don't have to finish/drywall behind the access panel. The receptacle and box need to be properly mounted and the power cable feeding it needs secured.My issue is that I need to install new work boxes so that they extend 1 1/4" beyond the stud. This way, when my second layer of 5/8" drywall goes up, it will be flush. I don't have enough depth with the boxes I am using to go out 1 1/4", so I am wondering if I can extend it 1 1/8" instead.

should electrical boxes be flushed

The key takeaway here as far as installing electrical boxes is that, by setting them flush with the drywall surface, the possibility of arcing from the wires to the wall substrate is minimized, which reduces the risk of an electrical fire. boxes should be flush with outside of drywall, however i believe you're allowed 1/4 if they are non-metallic. You don't want the box to stick out..but it's ok for it to be recessed a bit.. When you install the recept, the tabs on it will (should) cinch up against the drywall. The code says that the face of the box must be flush with the finish surface of the wall or less than 1/8 inch recessed. We do not care what hack tricks work for you. We care about giving professional advice. The box/mudring doesn't need to be flush on a non combustible wall finish (like drywall), it can be recessed up to 1/4 inch. This 1/8 inch gap rule applies to how big of a gap is allowed between the edge of the box/mud ring and opening in the finish.

The simple answer is that, if the box is flush with your mounting surface, it might be compliant as-is after tiling. If not (i.e. your tile is over 1/4"), you can make it compliant with an extension ring that does indeed use long mounting screws. No gap is allowed between the front of a panel box and the wall surface that the dead front of a recessed panel will sit against in a regular wood stud (combustible) wall structure, but a 1/4” gap is acceptable in a noncombustible (steel stud or concrete) wall construction.

Gaps around boxes that are recessed in noncombustible surfaces (such as plaster, drywall, or plasterboard) must be repaired so there will be no gap greater than 1⁄8 in. at the edge of the box (Fig. 2).

The NEC 314.29 prohibits covering up boxes such that you'd need to remove "part of the building" to access the wires inside. The drywall is considered "part of the building." You can move or extend them so the boxes are flush with the drywall when you're finished, so you can access the wiring by removing the cover. Box depth (behind drywall) is 1-1/2" giving 21 cubic inches. Mud ring is any depth you want, from 1/16" to 1-1/4", just match to your actual drywall thickness. That means the metal will be flush to your drywall and no need for spacers.My issue is that I need to install new work boxes so that they extend 1 1/4" beyond the stud. This way, when my second layer of 5/8" drywall goes up, it will be flush. I don't have enough depth with the boxes I am using to go out 1 1/4", so I am wondering if I can extend it 1 1/8" instead.

The key takeaway here as far as installing electrical boxes is that, by setting them flush with the drywall surface, the possibility of arcing from the wires to the wall substrate is minimized, which reduces the risk of an electrical fire. boxes should be flush with outside of drywall, however i believe you're allowed 1/4 if they are non-metallic. You don't want the box to stick out..but it's ok for it to be recessed a bit.. When you install the recept, the tabs on it will (should) cinch up against the drywall.

The code says that the face of the box must be flush with the finish surface of the wall or less than 1/8 inch recessed. We do not care what hack tricks work for you. We care about giving professional advice. The box/mudring doesn't need to be flush on a non combustible wall finish (like drywall), it can be recessed up to 1/4 inch. This 1/8 inch gap rule applies to how big of a gap is allowed between the edge of the box/mud ring and opening in the finish.

sheetrock electrical boxes

The simple answer is that, if the box is flush with your mounting surface, it might be compliant as-is after tiling. If not (i.e. your tile is over 1/4"), you can make it compliant with an extension ring that does indeed use long mounting screws. No gap is allowed between the front of a panel box and the wall surface that the dead front of a recessed panel will sit against in a regular wood stud (combustible) wall structure, but a 1/4” gap is acceptable in a noncombustible (steel stud or concrete) wall construction. Gaps around boxes that are recessed in noncombustible surfaces (such as plaster, drywall, or plasterboard) must be repaired so there will be no gap greater than 1⁄8 in. at the edge of the box (Fig. 2). The NEC 314.29 prohibits covering up boxes such that you'd need to remove "part of the building" to access the wires inside. The drywall is considered "part of the building." You can move or extend them so the boxes are flush with the drywall when you're finished, so you can access the wiring by removing the cover.

ciclos fijos torno cnc fanuc

cincon fabrica de metales pintados

The Honeywell Model 6209 Large Steel Security Box features a key lock with 2 entry keys included, a solid steel construction to protect your valuables, and 2 carry handles for convenient moving of the box.

electrical box is ressessed behind drywall needs to be flush|electrical box flush with drywall