zero offset in cnc machine CNC Machining . Okuma Lathe "z" work shift . To do that in the easiest to understand manner you'd want to set the Z zero offset to zero when you touch off T1, and then also set T1 Z offset=zero. . so that the present machine position will take the required actual position data and calculate where the program zero will be from the machine .

The best metal house plans. Find metal-framed barndominium floor plans with garages, 3-4 bedrooms, open layouts & more. Call 1-800-913-2350 for expert support.

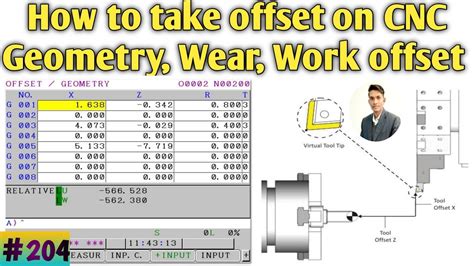

0 · what is wear offset

1 · what is tool length offset

2 · offset turning on cnc lathe

3 · offset meaning in cnc programming

4 · offset in cnc lathe

5 · geometry vs wear offsets

6 · cnc work offsets

7 · cnc tool offsets explained

Like the fact that some houses, particularly in the northeast, have a five-pointed decorative star hanging on the exterior. It’s been cited as being indicative of everything from religion to.

Learn all about CNC offsets and how they are used in CNC machining. Includes info on how to use them and what to watch out for. Setting zero on a CNC lathe is a crucial step in ensuring accurate and precise machining. Without properly setting zero, the machine may not know where the workpiece is located, leading to incorrect cuts and wasted material. In this article, here are three ways for how to set zero point in CNC or how to zero a CNC mill with stock before machining. This is how it looks in the offset file on a Haas machine. This is an imperial (inch) machine so this datum is 12.568 inches away from the X zero and 8.489 from the Y zero. On the Fanuc control below it has values set in G54 .

Cnc offsets and machine reference explained. In this post I am going to explain what cnc offsets are, how they are used, and how they relate to a machine reference point or home position. But first I should begin by explaining the .

CNC Machining . Okuma Lathe "z" work shift . To do that in the easiest to understand manner you'd want to set the Z zero offset to zero when you touch off T1, and then also set T1 Z offset=zero. . so that the present machine position will take the required actual position data and calculate where the program zero will be from the machine . 11 Ways to Locate Part Zero on Your CNC Machine. Originally published in 2016, this article providing 8 strategies for locating Part Zero gained immense popularity. . It simply has to be located at a known offset so that once you’ve found the feature, you can apply the .

A subreddit for enthusiasts of Hobbyist CNC machines like the Shapeoko, X-Carve, 6040, etc . Part/Program Zero = Work Offset position – the center or lower left-hand corner of your workpiece, usually three individual buttons on the DRO display used to Zero Out the Part/Program location for X, Y, Z axes. As you know, Fanuc-controlled machining centers come with at least six fixture offsets, invoked in a program by G54 through G59 respectively. When the machine executes a G54, for example, it knows to look at the registers in fixture offset number one to find the program zero assignment values for the current coordinate system. (G59, of course, tells the machine .Study with Quizlet and memorize flashcards containing terms like __________ or program zero point is more common as a reference point than using machine coordinates., Machine zero can be located in __________ depending on manufacturer and machine type., Which of the following does the programmer define as the origin of measurements on the workpiece? and more.The axis-by-axis home search cancels the zero offset, the fixture offset and the measuring offset. The CNC assumes the machine reference zero point (home) as the new part zero. Automatic home search (with subroutine). JOG MODE. Softkey. Description. Change the units for data display (mm or inch es). For programming, the CNC assumes the

what is wear offset

In the world of Computer Numerical Control (CNC) machines, achieving accurate zero settings is crucial for ensuring precise machining operations. Zero setting refers to the process of establishing the reference point from which all measurements and movements are determined. . 4.2 Tool Length Offset:\ Considering the length of the tool is . CNC BASIC CAD CAM1158, KRISHNA NAGAR, OPPOSITE- UTTAM INDUSTRIESMEERUT ROAD, GHAZIABAD, UTTAR PARDESH , PIN 201002📞📕CALL or WHATSAPP 09910440210 , 0813.Of course the feature doesn’t have to be at part zero. It simply has to be located at a known offset so that once you’ve found the feature, you can apply the offset to get part zero. Method 7: End mill Plus Paper, Feeler, or Gage Block. Finding part zero with .

I have an HMC with an OM control. If I start the program with the axis anywhere but home; when I give it a G54,G55 etc, It measures it from where I'm starting, not from machine zero. For instance, my G54 is X 1.5 Y-2. Z -15. If my machine coordinates are at X0Y0Z0 when I start, it works as it should. If my machine coordinates are, for example . Geometry offset is usually set from machine zero, but this is not mandatory. There are different ways of how to set the X and Y offsets, and CNC operators find many ingenious ways. Many modern lathes have a feature that sets the offset automatically. Manually, each axis is measured individually. . At the CNC machine, offsets are entered via . If it happens to be one particular tool, then the Offset of that tool will be taken into account. Sinha in Post #3, in his explanation of setting the Work Offset System Offset for a lathe, referred to using a Master Tool having preferably a Zero Offset. For many years, its been uncommon for any tool to have a Zero Value for either X or Z. Enter the distance in the offset menu of the CNC control software. Repeat the process for all axes. How to Zero a CNC Machine. . To zero a CNC machine, the operator must locate the home position of each axis and then set their respective zero positions. This process is usually done using a touch probe or edge finder to accurately measure the .

seems you are always placing your stock relative to machine zero and not changing the G54 offset from 0. Fine, but you are missing out on the convenience of separating machine 0 from work 0, and this is causing your confusion about changing machine co-ordinates. simply put, you DONT change machine co-ordinates, you change work offsets.

Coordinate systems tell a CNC machine where to position the cutting tool during the program’s execution for any purpose that requires the cutting tool to move. View From My Shop See All . 24 Oct 2024. Inside .

This should be the "GEOMETRY" column in your tool offset table. You're done; If I'm working on a machine without a tool probe, I often like to double check the offset with a size block. If you've already set your work offset Z zero (more on that in a moment) go in MDI and type in something like this example in order: G90 G54 G0 G43 Z3.0 H1 CNC Control Procedures (Okuma OSP & FANUC): “Work Zero Offset” 01.14.2015 See a demonstration of Okuma OSP CNC Control and FANUC Control Side-by-Side as the "work zero offset" is performed.

1099 r box 7 distribution code 6

Zeroing the Machine: The first step in setting a work offset is establishing a zero or home point on the machine. This benchmark is usually in relation to the machine, the part, or the machine's spindle. 2. Establishing the Part Zero: This is the second step, which involves translating the machine zero to the part zero. This operation requires . Once the CNC operator sets the work off set as the distance between machine zero and part zero, the tool motion should end at the position that matches the drawing dimension. If the motion is activated before the work offset .It kinda sounds like using the CNC Work Offsets G54 to G59, might be the easiest way, as long as you leave the original origins (zero positions) alone in the design file. If I had the option, I would set the offset at the driver controller.

100mm steel box section weight

In this crude drawling when I touch off the 2" side of the 1-2-3 block the machine's Z reads -18.000" so in the offset page under the tool number I'm using, I hit tool offset measure button then with same tool selected go to command and type -2.000 enter or (+ -2.000) which allows for 2" block/standard that will set the table at -20.000 machine .There are several types of reference points commonly used in CNC machining, including machine zero, workpiece zero, and tool length offset. Machine Zero:\ Machine zero, also known as the machine home position, is the reference point that defines the coordinate system for CNC machines. It represents the origin of the machine's X, Y, and Z axes. By entering these dimensions into the machine controller work offset tables, we can define these new zero locations on the machine. We can then use these new zero locations by calling up the desired work offset in the NC program. Work Offset Table Values (In the CNC machine controller): G54 X10.000 Y12.000 G55 X20.000 Y12.000

Tool Offset Process. The tool offset of the CNC control system is the process of calculating the tool center trajectory carried out by the CNC system. . the compensation value is the tooltip movement distance when the spindle moves from Z coordinate zero of the machine tool to program zero of the workpiece, so the compensation value is always .The machine zero may seem random, it's used by the manufacturer as a starting point, then the G54 G55 etc are offset from that point and used to make parts. Of you smacked the machine and the carriage moved on the screw, it could be mechanically off and create the situation you have (don't ask me how I know).The Role of Machine Zero Point in CNC Operations\ The machine zero point plays a vital role in ensuring the success of CNC operations. This section will highlight its significance in various stages of machining, such as tool changes, workpiece positioning, and multi-axis operations. Furthermore, it will discuss how deviations from the zero . - at this moment, Z offset represents a real distance, relative to turret frontal [ encoders origin calibration ] *path : parameters \ sys para 2 \ * base zero offset *path : parameters \ optional parameter ( other function ) \ spindle orientation zero offset - MDI : reset all origins : XZYCW to be 0

what is tool length offset

offset turning on cnc lathe

I truly love to metal detect old house sites over the past 5 decades. I found old coins, lots of old artifacts, and more. See my metal detecting tips for older homesites.

zero offset in cnc machine|what is tool length offset