12 gauge sheet metal tolerances Sheet Metal Guage Tolerances. During the rolling process the rollers bow slightly, which results in the sheets being thinner on the edges. The tolerances in the table and attachments reflect current manufacturing practices and commercial standards and are not representative of the . Dry run is intended to help you check out your program by "cutting air". All the programmed feedrates are increased and (optionally) all the rapid motions are decreased. In Dry Run, you should be able to control the speed of both .

0 · steel plate thickness tolerance chart

1 · steel gauge tolerance chart

2 · standard sheet metal tolerances chart

3 · stainless steel sheet tolerance chart

4 · sheet thickness tolerance chart

5 · sheet metal tolerances chart

6 · sheet metal thickness tolerance chart

7 · astm sheet metal gauge chart

Electrical enclosures are prone to fires that can be very intense (in the order of the megawatt) and are hence an important topic of fire safety engineering. See more

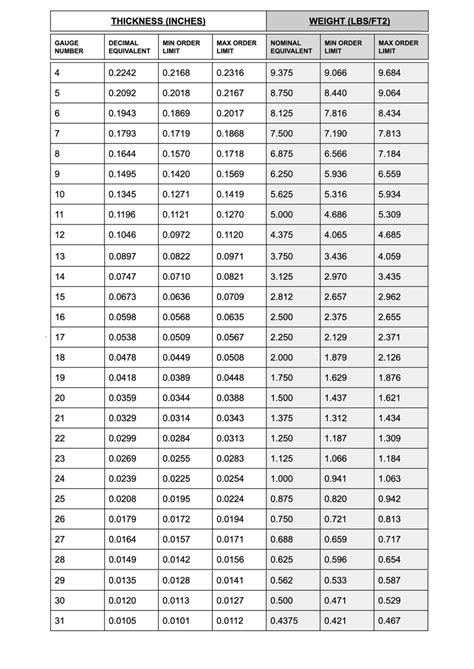

Sheet Metal Guage Tolerances. During the rolling process the rollers bow slightly, which results in the sheets being thinner on the edges. The tolerances in the table and attachments reflect current manufacturing practices and commercial standards and are not representative of the .The following charts give typical ASTM and ANSI steel sheet mechanical tolerance .Tolerances: Sheet metal tolerances should not be tighter than necessary to make . The following charts give typical ASTM and ANSI steel sheet mechanical tolerance .

Tolerances: Sheet metal tolerances should not be tighter than necessary to make the . The below table summarizes sheet metal gauge and tolerances. Monroe, nor any of .

Below is our best attempt to capture all of the standard gauge thickness of different materials. Be sure to check with your supplier when purchasing steel what your actual thickness is going to .Gages 10, 11, 12 – tolerances shown are for widths over 40” to 60” inclusive All other gages – tolerances shown are for widths over 32” to 60” inclusive

Hot rolled P&O gages 4 through 18 - tolerances shown for widths over 40" to 48" inclusive. All other gages over 15" to 72" inclusive.Gauges 10, 11, 12 - tolerances shown are for widths over 40" to 60" inclusive. All other gauges -- tolerances shown are for width over 32" to 60" inclusive.Sheet Metal Guage Tolerances. During the rolling process the rollers bow slightly, which results in the sheets being thinner on the edges. The tolerances in the table and attachments reflect current manufacturing practices and commercial standards and are not representative of the Manufacturer's Standard Gauge, which has no inherent tolerances.

The following charts give typical ASTM and ANSI steel sheet mechanical tolerance ranges. Carbon Steel Sheets. Galvanized Steel Sheets.Tolerances: Sheet metal tolerances should not be tighter than necessary to make the part functional. Tight tolerances raise the cost of manufacturing significantly. Practical tolerances vary according to the design requirements. Tolerances of +/- .010 should be considered minimum. Linear tolerances should be held as loose as possible.The below table summarizes sheet metal gauge and tolerances. Monroe, nor any of its employees shall be held liable for any improper or incorrect use of the information described and/or contained herein and assumes no responsibility for anyone's use of the information.

Below is our best attempt to capture all of the standard gauge thickness of different materials. Be sure to check with your supplier when purchasing steel what your actual thickness is going to be, especially if you’re receiving polished or treated material.Gages 10, 11, 12 – tolerances shown are for widths over 40” to 60” inclusive All other gages – tolerances shown are for widths over 32” to 60” inclusive

Hot rolled P&O gages 4 through 18 - tolerances shown for widths over 40" to 48" inclusive. All other gages over 15" to 72" inclusive.

Gauges 10, 11, 12 - tolerances shown are for widths over 40" to 60" inclusive. All other gauges -- tolerances shown are for width over 32" to 60" inclusive.Useful tables of standard specifications and tolerances pertaining to sheet and bar steel products. The manufacturing process used for specific features in sheet metal fabrication impacts tolerances. While features located on the same surface can achieve standard tolerances of +/- 0.005", formed features like flanges have looser tolerances due to stretching during forming.

steel plate thickness tolerance chart

Sheet Metal Guage Tolerances. During the rolling process the rollers bow slightly, which results in the sheets being thinner on the edges. The tolerances in the table and attachments reflect current manufacturing practices and commercial standards and are not representative of the Manufacturer's Standard Gauge, which has no inherent tolerances.

The following charts give typical ASTM and ANSI steel sheet mechanical tolerance ranges. Carbon Steel Sheets. Galvanized Steel Sheets.Tolerances: Sheet metal tolerances should not be tighter than necessary to make the part functional. Tight tolerances raise the cost of manufacturing significantly. Practical tolerances vary according to the design requirements. Tolerances of +/- .010 should be considered minimum. Linear tolerances should be held as loose as possible.The below table summarizes sheet metal gauge and tolerances. Monroe, nor any of its employees shall be held liable for any improper or incorrect use of the information described and/or contained herein and assumes no responsibility for anyone's use of the information.

Below is our best attempt to capture all of the standard gauge thickness of different materials. Be sure to check with your supplier when purchasing steel what your actual thickness is going to be, especially if you’re receiving polished or treated material.

Gages 10, 11, 12 – tolerances shown are for widths over 40” to 60” inclusive All other gages – tolerances shown are for widths over 32” to 60” inclusiveHot rolled P&O gages 4 through 18 - tolerances shown for widths over 40" to 48" inclusive. All other gages over 15" to 72" inclusive.Gauges 10, 11, 12 - tolerances shown are for widths over 40" to 60" inclusive. All other gauges -- tolerances shown are for width over 32" to 60" inclusive.Useful tables of standard specifications and tolerances pertaining to sheet and bar steel products.

steel gauge tolerance chart

The fiber laser changed the laser cutting game, not just for its speed but for its wavelength. The CO 2 laser beam’s 10.6-micron wavelength had decades of success since .

12 gauge sheet metal tolerances|standard sheet metal tolerances chart