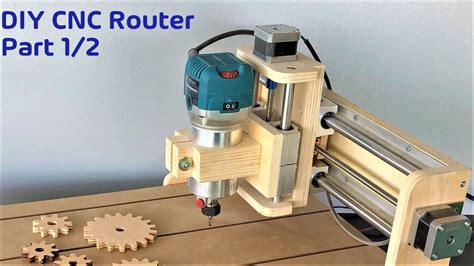

diy cnc router printer parts Since most of the parts are recovered from my old CNC and the design preference was not to cut any of the longer rails into a shorter one and . West Air Sheet Metal, Mechanical, Heating, Air Conditioning, Plumbing Products and .

0 · homemade cnc router plans

1 · homemade cnc router parts

2 · homemade cnc router machine

3 · homemade cnc parts

4 · hobby cnc router parts

5 · hobby cnc diy control panel

6 · diy cnc kit and parts

7 · build it yourself cnc router

Still, it’s possible to weld thin sheet metal using the MIG (GMAW), TIG (GTAW), and stick (SMAW) processes. But MIG and TIG provide the best results. This article will teach you how to weld thin gauge metal using each arc .

Most of the mounts and small parts are made from easily worked PVC sheet stock. Precision rails were scavenged from old Ricoh copiers. .I will try to make it easy for you by offering the common component that can be used in your DIY CNC Router. These parts are especially selected to work with motors used in the DIY .Since most of the parts are recovered from my old CNC and the design preference was not to cut any of the longer rails into a shorter one and .I have created 2d drawings of all the parts with complete dimensions and specs, details on how to build each part, a complete parts and tools lists with prices and links, a basic wiring diagram and an explanation of the design.

This is a Kyo Sphinx CNC Router build. Working Area: 350mm X 500mm Link to original design: https://openbuilds.com/builds/c-beam-sphinx.3605/ While 3D printers fabricate parts by adding material over time, CNC mills and routers fabricate parts by subtracting material. That is preferable when working with large parts or when you require a lot of precision. If you want an .

Bring your boldest ideas to life with CNC routers that deliver precision, durability, and ease of use. Whether you’re a hobbyist or a professional, our machines are built to help you turn imagination into reality. Most of the mounts and small parts are made from easily worked PVC sheet stock. Precision rails were scavenged from old Ricoh copiers. Epson printers provided the tubing which became motor.

add sheet metal tab solidworks

I will try to make it easy for you by offering the common component that can be used in your DIY CNC Router. These parts are especially selected to work with motors used in the DIY community and took me quite a while to find the perfect combinations.

This is the full build of the CNC router. Using aluminium profiles as a frame and 3D printer parts to connect everything together. So far it works pretty well! Features / specs. It’s not the strongest thing, lets be honest, but it does the job well enough for me. The NEMA 17 steppers aren’t really strong enough for high feedrates.Since most of the parts are recovered from my old CNC and the design preference was not to cut any of the longer rails into a shorter one and because of that approach, I am able to build a larger footprint 3 in 1 CNC machine.I have created 2d drawings of all the parts with complete dimensions and specs, details on how to build each part, a complete parts and tools lists with prices and links, a basic wiring diagram and an explanation of the design.

This is a Kyo Sphinx CNC Router build. Working Area: 350mm X 500mm Link to original design: https://openbuilds.com/builds/c-beam-sphinx.3605/

While 3D printers fabricate parts by adding material over time, CNC mills and routers fabricate parts by subtracting material. That is preferable when working with large parts or when you require a lot of precision. If you want an affordable option, this guide will show how to build Ivan Miranda’s 3D-printed CNC machine design. DIY CNC routers have a lot to offer. Find out more about CNC router parts and get some guidance to join the fun.This guide goes through all the steps to build your own CNC machine from scratch. It includes a complete bill of materials (BOM), STL/OBJ-files for all the 3d-printed parts and detailed instructions of how everything is assembled.

Bring your boldest ideas to life with CNC routers that deliver precision, durability, and ease of use. Whether you’re a hobbyist or a professional, our machines are built to help you turn imagination into reality. Most of the mounts and small parts are made from easily worked PVC sheet stock. Precision rails were scavenged from old Ricoh copiers. Epson printers provided the tubing which became motor.I will try to make it easy for you by offering the common component that can be used in your DIY CNC Router. These parts are especially selected to work with motors used in the DIY community and took me quite a while to find the perfect combinations.

This is the full build of the CNC router. Using aluminium profiles as a frame and 3D printer parts to connect everything together. So far it works pretty well! Features / specs. It’s not the strongest thing, lets be honest, but it does the job well enough for me. The NEMA 17 steppers aren’t really strong enough for high feedrates.

Since most of the parts are recovered from my old CNC and the design preference was not to cut any of the longer rails into a shorter one and because of that approach, I am able to build a larger footprint 3 in 1 CNC machine.I have created 2d drawings of all the parts with complete dimensions and specs, details on how to build each part, a complete parts and tools lists with prices and links, a basic wiring diagram and an explanation of the design.

This is a Kyo Sphinx CNC Router build. Working Area: 350mm X 500mm Link to original design: https://openbuilds.com/builds/c-beam-sphinx.3605/ While 3D printers fabricate parts by adding material over time, CNC mills and routers fabricate parts by subtracting material. That is preferable when working with large parts or when you require a lot of precision. If you want an affordable option, this guide will show how to build Ivan Miranda’s 3D-printed CNC machine design.

DIY CNC routers have a lot to offer. Find out more about CNC router parts and get some guidance to join the fun.

homemade cnc router plans

add 3rd connection110 junction box

homemade cnc router parts

homemade cnc router machine

$45.00

diy cnc router printer parts|homemade cnc router machine