joining 2 sheet metal parts Riveting is a semi-permanent and non-thermal joining method that involves using a mechanical fastener /rivet (a metallic part with a dome-shaped head) to join sheet metal parts. Riveting involves drilling a hole in the two .

Vintage Decorative DAHER Metal Tin Container Lid Floral Design England 11101, Vintage Daher Long Island NY Round Tin, Morethebuckles

0 · sheet metal joining without fasteners

1 · sheet metal joining techniques pdf

2 · sheet metal joining techniques

3 · sheet metal joining screws

4 · permanent metal joining

5 · join metal without welding

6 · five methods of joining metals

7 · different joining methods for metal

$21.00

sheet metal joining without fasteners

Sheet metal joining operation is crucial part of the sheet metal fabrication process. Joint reliability depends on its type, sheet metal material, and manufacturing process. This article covers various types of sheet metal joining techniques, . In this post, we'll compare some of the most common techniques for joining sheet metal parts: Tapped Holes. Tapping involves cutting threads directly into the sheet metal to .

philip crangi metal box

Sheet metal joining methods include both temporary and permanent solutions as well as those that require additional parts and pre-work. These methods include, mechanical fastening, welding, rivets, brazing and soldering, tongue and . Effective joining of sheet metal parts is a critical stage of the sheet metal fabrication process. In this article we’ll take a look at five standard methods of joining sheet metal and .Two standard methods employed for metal joining are Welding and Fabrication. In this comprehensive guide, we will dive deeper into metal joining, exploring the welding and metal fabrication processes, their differences, applications, and .

Riveting is a semi-permanent and non-thermal joining method that involves using a mechanical fastener /rivet (a metallic part with a dome-shaped head) to join sheet metal parts. Riveting involves drilling a hole in the two . Hello, I want to extend exactly between the two sheet metal plates in the design I have shared the screenshot, but I could not do it, with which method I can extend the two parts to each other exactly.

Solved: I want to connect two sheet metal faces with a bend. Bend works if two parallel edges are selected. Is there a way to connect two faces with. Autodesk Community > Inventor Community > . I hade to delete the faces on the edge and have them heal on the 2 parts that are parallel. Also make sure all the sheet metal thickness is the same . Snap Fits Sheet Metal Assembly. 9. Joining Sheet Metal Using Clinching. Sheet metal assembly using clinching is used for two flat sheet metals. It will enable you to create a button type between these sheet metal parts. . I do a lot of sheet metal models and if I do a sketch then flange it to my desired sheet metal rule flat pattern works great. If I need to add another body to extend the original part or extend a part of it by doing another sketch off the first sketch, then flange in the right direction so it looks like it should be one piece I always get a line separating the new body from the old .

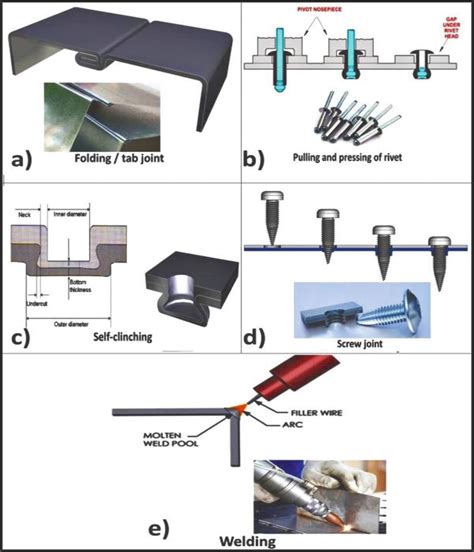

It ’ s a challenging t ask to join sev eral sheet metal parts in a cost-eff ective and . secure mann er. The v ery commonl y used con ventional m ethods of joining sheet metals are shown .Hi, I created this rectangular sheet metal 'part' by creating one quadrant and applying 'mirror' two times. In the parts list and flat view I now have four parts which I want to have as one. Boolean is not allowed active for sheet metal. I dont know if 'finsh sheet metal model' would help but I can apply finish only to one of the four parts anyway. Appliance engineers have several options for joining sheet metal, including screws, rivets, welding, bonding, clinching and folding. Which is best depends on the material, its thickness and the application requirements. Most engineers rely heavily on mechanical fasteners. . “Clinching keeps parts together while the adhesive cures.” . Metal sections that are 0.5 inch or thicker can be handled with almost equal efficiency by both methods. Thinner sections are better joined by brazing. Here is an example. You want to adopt brazing when you’re working to create a T-joint bonding a piece of sheet metal to metal stock where the thickness of both pieces is 0.5 inch.

The Base Flange and Edge Flange commands let you merge bodies in a multibody sheet metal part.. You can merge sheet metal bodies of the same thickness by: Using the Up to Edge and Merge option when inserting an edge flange between two bodies with parallel linear edges.; Using the Merge result option when adding a base flange that overlaps the profiles of multiple bodies . Thank you Ryan. I ended up creating new blank components and recreated the sheet metal parts in there. The Joint functions are now working. In the past I had created new files and bringing in derives, unlinking them, converting them back into sheet metal parts and inserting them into an "Assembly" file.Sheet metal joining is a crucial aspect of fabrication that can make or break the durability, functionality, and aesthetics of your projects. . Master the art of assembling laser-cut sheet metal parts with captive nuts - a cost-effective, tool-free method ideal for hobbyists and prototypers. Table of Contents. Welding: The Gold Standard of .Currently there is no way to join two completed separate sheet metal Bodies created by two sheet metal master features. A way around this is to create an envelope part that represents the final volume of the part as a normal solid and use the thicken or convert option to have all the relevant faces included in the same sheet metal feature or .

METHOD OF JOINING TWO SHEET METAL PARTS Abstract of Disclosure A method of joining first and second sheet metal parts along a common seam formed from a first surface on the first part and a second surface generally machine the first surface and of the second part. These surfaces define therebetween random spaces of variable thickness when the surfaces are .Engineers apply the knowledge of math & science to design and manufacture maintainable systems used to solve specific problems. AskEngineers is a forum for questions about the technologies, standards, and processes used to design & build these systems, as well as for questions about the engineering profession and its many disciplines. The ability to choose the most appropriate material for a particular application can significantly enhance the functionality and lifespan of the product. The role of materials in sheet metal fabrication is indeed a fascinating one, .

The brazing method means using a sort of filler metal to connect two metal parts together. The filler metal is heated at a temperature of over 800 degrees. While this method is like welding, it’s less costly. Plus, it’s more like .DIN 8593 Part 1 is about simple joining. The parts are . placed one over another, joining, articulating and locking . (QFD) tool to select the joining process in sheet metal assembly by . The primary difference between these three methods of joining metal is temperature: Soldering and brazing both involve melting a filler metal with a lower melting point than the two parts to be joined, and rely on capillary action to draw that filler into the seam, creating a strong bond. Sheet metal fabrication is the act of forming, shaping, and joining metal together to build and or repair a tangible part. There are many techniques and tools. It’s been done since the beginning of time when even the simplest tools were used. In this article we will share the most common and important tools, machines, and techniques for the DIY fabricator.

The twist at the join looks right to me for a sheet metal part, if you're referring to the surfaces I've highlighted in one attachment. Note, I rolled back before the Cut-Extrude5 feature, which creates unrealistic sheet metal geometry as it shaves off the flange edges a little, as seen in the other attached picture. 3 Consult Your Sheet Metal Fabricator about the Optimal Joining Method. 3.1 Joint and weld solutions; 3.2 Other joining solutions; 4 Sheet Metal Part Design for Manufacturing Tip. 4.1 CORNERS AND WELDING; 5 Sheet Metal Fabrication Weld Joints FAQ. 5.0.1 What are the primary considerations when choosing between open and closed corner joints for . 3. Hot Plate Welding . Hot plate welding adopts a drawer-like structure where heat from the hot plate machine is transferred to the fusion surface of the upper and lower plastic heating components through electrical heating. This melts their surfaces, after which the hot plate machine is quickly withdrawn, allowing the molten surfaces of the two heated components to . Sheet metal assemblies using hooks or slot-and-tabs to hold parts together are not new. Hooks or equivalent structures remain involved in a snap-fit connection, holding the parts together in all degrees of freedom but one. A hook-and-latch connection is then integrated, preventing back-out, thereby locking the part in place.

Joining butted sheet metal parts. CM By Chris Manger 09/23/10. Not really a SolidWorks question, more of a design question. Im curious on how others join butted sheetmetal parts, meaing 2 flat parts welded together to make a longer part. Rectangle slots, dovetails, etc. answers: 8.The invention relates to a method for joining two sheet-metal parts (2, 3) together by adhesive bonding and welding along a join line (4), comprising the following successive steps: - partially inserting at least one self-piercing rivet (5) into an edge (2A) of the first part (2) at the join line, - depositing a plurality of beads of glue (6) discontinuously along the join line at the edge (2A .

Fig. 2 Radial riveting equipment and riveting process. Process selection and precautions of riveting (1) The size of the riveting bottom hole should be designed in strict accordance with the manuals of general or special equipment, standard parts, and should comprehensively consider the material, thickness, model, and strength requirements of the .Metal parts are spot welded together. To prevent corrosion of the parts a thixotropic, non hardening, corrosion resistant material including a solvent and having a negligible gravity flow at temperatures less than about 400° F to 440° F and forming a heat insulating coherent gel when burnt is used between the plates. The material is known as Anchor Tuflex #23.

sheet metal joining techniques pdf

sheet metal joining techniques

phone cable junction box

sheet metal joining screws

$15.99

joining 2 sheet metal parts|sheet metal joining screws