edge to hole distance in sheet metal Sheet Metal gauge chart converts sheet thickness from gauge to mm or inch. . Types of CNC Machine? 1. CNC Plasma Cutting Machine. for cutting metals for a wide variety of purposes. 2. CNC Laser Cutting Machine. others. 3. CNC Milling Machine. both drilling and turning machines. 4. CNC Router Machine. 5. CNC .

0 · sheet metal rib design guidelines

1 · sheet metal fabrication design guide

2 · sheet metal extruded hole design

3 · sheet metal drawing standards

4 · sheet metal drawing dimensioning

5 · sheet metal corner relief chart

6 · sheet metal bending guide pdf

7 · minimum flange length sheet metal

Here are the top 11 best ceiling fan box options: The Westinghouse 0152500 Saf-T-Bar is a strong, 24-inch-long bar with an all-metal electrical box. It comes with a Romex connection, mounting gear, and a unique Saf-T-Cap, which protects the bolts and wires during painting and drywall installation.

sheet metal rib design guidelines

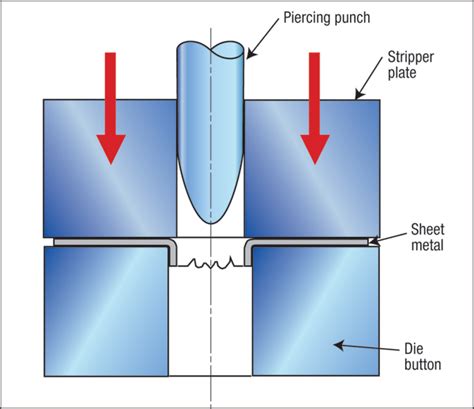

The minimum distance between hole/slot edge to bend edge avoid metal distortion, deformation, and fracturing. The recommended minimum distance between hole /slot edge to bend in sheet metal parts is three times the sheet thickness plus bend radius.K Factor in sheet metal bending is a constant used to calculate sheet metal .Sheet Metal gauge chart converts sheet thickness from gauge to mm or inch. . 3. The minimum distance between the hole or slot and the edge of the sheet should be three times of sheet thickness. Min. Edge-to-hole distance= 3 x thickness. 4. If the custom sheet metal fabrication design has semi-pierced .

It is recommended that the minimum distance between the extruded holes to part edge should be at least three times the thickness of sheet. Certain distance should be maintained between two extruded holes in sheet metal designs. If extruded holes are too close it .Sheet Metal Fabrication is the process of forming parts from a metal sheet by punching, cutting, stamping, and bending. 3D CAD files are converted into machine code, which controls a machine to precisely cut and form the sheets .Holes should be placed away from the curl at least a distance of the radius of the curl plus the material’s thickness. Bends should be at least 6 times the material’s thickness plus the radius of the curl. The maximum depth a countersink may have is .6 times the material’s thickness.

Outlined below are the minimum distances to be maintained between a gusset and other features like edges and holes in sheet metal components. These guidelines are calculated considering the material .The minimum distance between hole/slot edge to bend edge avoid metal distortion, deformation, and fracturing. The recommended minimum distance between hole /slot edge to bend in sheet metal parts is three times the sheet thickness plus bend radius.Edge bulging-restrictive tolerances on V bends may result in edge bulging—provide bend relief accordingly. Hole-to-form-distance from hole-to-form—to avoid hole distortion, place holes no less than 2.5 times the material thickness + bend radius from the bend itself. 3. The minimum distance between the hole or slot and the edge of the sheet should be three times of sheet thickness. Min. Edge-to-hole distance= 3 x thickness. 4. If the custom sheet metal fabrication design has semi-pierced or extruded holes, the distance from the edge or bend to them should be three times of sheet thickness.

It is recommended that the minimum distance between the extruded holes to part edge should be at least three times the thickness of sheet. Certain distance should be maintained between two extruded holes in sheet metal designs. If extruded holes are too close it .Sheet Metal Fabrication is the process of forming parts from a metal sheet by punching, cutting, stamping, and bending. 3D CAD files are converted into machine code, which controls a machine to precisely cut and form the sheets into the final part.Holes should be placed away from the curl at least a distance of the radius of the curl plus the material’s thickness. Bends should be at least 6 times the material’s thickness plus the radius of the curl. The maximum depth a countersink may have is .6 times the material’s thickness.

Outlined below are the minimum distances to be maintained between a gusset and other features like edges and holes in sheet metal components. These guidelines are calculated considering the material thickness and the specific features involved, aiming for a balanced and efficient design. To avoid workpiece failure, DFM guidelines recommend a minimum distance (D1) from hole to the sheet edge equal to at least the plate thickness (T); we recommend a safe design zone of 1.5 to 2T. Also, when piercing multiple holes, we recommend a spacing between holes (D2) greater than 2T.

Factors like bend radius and feature-to-feature cut distances should be considered. Be sure to follow design requirements and tolerances in this guide to ensure parts fall closer to design intent. Why Use Sheet Metal? Sharp edges will be broken and deburred by default.

nd slots depend on the bend radius and metal thickness. For instance, if the thickness is 0.914mm or thinner, the hole should be at least 1.574mm from the edge and 3.175mm away if t. e thickness is thicker than 0.914mm to avoid distortion. Spacing hole appropriately also helps i.

The minimum distance between hole/slot edge to bend edge avoid metal distortion, deformation, and fracturing. The recommended minimum distance between hole /slot edge to bend in sheet metal parts is three times the sheet thickness plus bend radius.

Edge bulging-restrictive tolerances on V bends may result in edge bulging—provide bend relief accordingly. Hole-to-form-distance from hole-to-form—to avoid hole distortion, place holes no less than 2.5 times the material thickness + bend radius from the bend itself. 3. The minimum distance between the hole or slot and the edge of the sheet should be three times of sheet thickness. Min. Edge-to-hole distance= 3 x thickness. 4. If the custom sheet metal fabrication design has semi-pierced or extruded holes, the distance from the edge or bend to them should be three times of sheet thickness.It is recommended that the minimum distance between the extruded holes to part edge should be at least three times the thickness of sheet. Certain distance should be maintained between two extruded holes in sheet metal designs. If extruded holes are too close it .Sheet Metal Fabrication is the process of forming parts from a metal sheet by punching, cutting, stamping, and bending. 3D CAD files are converted into machine code, which controls a machine to precisely cut and form the sheets into the final part.

Holes should be placed away from the curl at least a distance of the radius of the curl plus the material’s thickness. Bends should be at least 6 times the material’s thickness plus the radius of the curl. The maximum depth a countersink may have is .6 times the material’s thickness.

sheet metal fabrication design guide

Outlined below are the minimum distances to be maintained between a gusset and other features like edges and holes in sheet metal components. These guidelines are calculated considering the material thickness and the specific features involved, aiming for a balanced and efficient design. To avoid workpiece failure, DFM guidelines recommend a minimum distance (D1) from hole to the sheet edge equal to at least the plate thickness (T); we recommend a safe design zone of 1.5 to 2T. Also, when piercing multiple holes, we recommend a spacing between holes (D2) greater than 2T.

Factors like bend radius and feature-to-feature cut distances should be considered. Be sure to follow design requirements and tolerances in this guide to ensure parts fall closer to design intent. Why Use Sheet Metal? Sharp edges will be broken and deburred by default.

electircal junction box

Rolling, stamping, spinning, drawing, stretch, rubber pad, super plastic, peen, explosive and magnetic pulse forming etc. Various types of sheet metal forming process and their features will be discussed here.

edge to hole distance in sheet metal|sheet metal drawing standards