metal fabrication tools and equipment pdf In this article, you will learn what are the welding tools and equipments? explained with Pictures. You can also download the PDF file. You can't put a Icon hutch on a US General cabinet with out lots of modifications. First the stainless steel top is required for the hutch. The stairs steel top won't fit the general boxes so you would have to modify or make something.

0 · trick tools website

1 · structural steel fabrication hand tools

2 · metal shaping tools and equipment

3 · list of metalworking tools

4 · hobby metal working tools

5 · hobby metal bending tools

6 · custom sheet metal fabrication tools

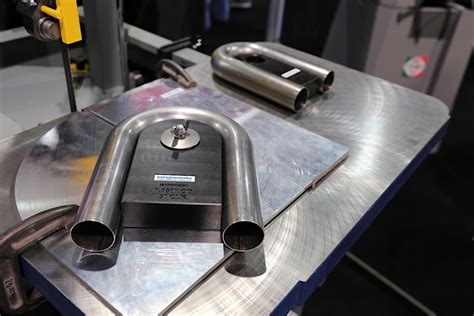

7 · automotive sheet metal fabrication tools

Yes, I use AutoCAD (and Revit) everyday. If you go into building engineering working with architects, you will use it constantly. A good/typical MEP consulting firm will put you under another PE as a designer doing/helping with their CAD work while you train under them.

metal fabrication creates components for a broad spectrum of industries from raw or semi-finished metal materials. A few of the most common techniques include laser cutting, forming, drilling, . In this article, you will learn what are the welding tools and equipments? explained with Pictures. You can also download the PDF file.Tube & Structural Processing. 1 - Mazak FabriGear 220 Fiber 4000 watt; 3⁄4” thru 6” square, 8 5/8”round outside dimensions, lengths up to 26 ft. CAPACITY: Material types include: Tube, .Tool List. 1st Year Students. -Welding Cap -Ear Muffs & Plugs -Welding Helmet -#10 - #12 Filter Lens -Clear Lens -Cutting Goggles/Glasses -#5 Filter Lens -Gauntlet Gloves -Safety Glasses .

FABRICATION WELDING 4. sion cord Plate/sheetme. al Gauge Laser thermometerTOTAL: 5.00 (APPX.)All of the above tools & supplies for Fab/Weld 1 Chalk Line (Plum Bob Type) .Trick Tools offers high performance metal fabrication equipment and metal working tools like tube benders, notchers, saws, English wheels, and sheet metal brakes.

trick tools website

.002.04From sheet metal and plate fabrication to structural members to architectural metal work and weldments, there are a lot of markets served by the fabrication process. Metal fabrication : a practical guide. by. O'Con, Robert L. Publication date. 2015. Topics. Metal-work, Travail des métaux, metalworking, Metals Forming. Publisher. Rockford, Ill. : Fabricators & Manufacturers .

In this article, we will explore the essential tools and equipment that every metal fabricator should have in their workshop. We will cover everything from hand tools and power tools to welding .ACE FABRICATION DIVISION || 484 Thomas Drive, Bensenville, IL 60106 847.455.1010 acemetal.com FABRICATION EQUIPMENT LIST AND CAPABILITIES Updated 8/23 Tube & Structural Processing 1 - Mazak FabriGear 220 Fiber 4000 watt; ¾” thru 6” square, 8 5/8”round outside dimensions, lengths up to 26 ft. CAPACITY: • Material types include: Meet the Author, Darren O’Brien: founder of Woodward Fab, is a pioneer in metal fabrication with over 50 years of experience. In this blog, he shares his expert knowledge on sheet metal fabrication tools, techniques, and innovations. Join Darren as he provides valuable tips and insights into industry trends from a true veteran of the field.

Metal fabrication : a practical guide by O'Con, Robert L. Publication date 2015 Topics Metal-work, Travail des métaux, metalworking, Metals Forming Publisher . Pdf_module_version 0.0.18 Ppi 360 Rcs_key .Advanced Metal Fabrication and Machine, Inc. is a full service metal fabrication, machining, and manufacturing shop located in Prescott Arizona. We offer a wide range of services including fabrication, machining, both for custom and production work. We also offer complete design services, and prototype development.Metal Fabrication and Welding (MFAB) Courses MFAB 124 Introduction to Welding (3 Hours) Introduction to Welding is a basic welding, tool, and equipment safety course. This course will expose students to the various welding processes and techniques. Tools, equipment and safety related to the metal fabrication area will be discussed and used by .

5.0 DISCUSSION 1. 5 safety measures while operating machines in metal fabrication lab. • Use safety goggles and wear safety shoes to protect against debris and heavy object • Check machines for any damage or malfunction. Ensure guards and safety features are in place and working. • Turn off machines and disconnect the power before maintenance or adjustments to .

Shop best quality Woodward fab's tools and equipment at best price with over 50 years of experience since 1966. Simplify your metalworking projects with our reliable solutions. Wishlist; Free Catalog; CALL 1-810-632-5419 . Woodward Fab is a leading manufacturer and supplier of a diverse range of high-quality sheet metal fabrication tools .

Remember, each tool is necessary, and you can’t achieve the desired results by using something else. Mastering these essential tools will help you excel during sheet metal fabrication. FAQs 1. What are the most common tools used in sheet metal fabrication? Common tools in sheet metal fabrication include shears, brakes, and welders.Metal Working Tools and Machines (sheet and small section steel) Author: Robert J. Fairchild Created Date: 10/29/2012 9:00:41 AM .Sheet metal fabrication involves punching, stamping, cutting, and bending metal sheets to form the desired shape. With technology, manufacturers use computer-aided 3D CAD programs to control the machines to cut and form the sheets into the final . and other equipment to create standard shapes such as U- or V-bends. . with standard .

Print PDF MOBI Pressbooks XML Book Description: . Basic principles and techniques of metal fabrication are introduced by planning and construction of fixtures used in fabrication from drawings. Basic tools and equipment for layout fitting of welded fabrications are utilized. Covers the use and application of the AWS welding symbols.Metal fabrication is a complex and demanding process that requires specialized tools and equipment. Whether you are a professional metal fabricator or a DIY enthusiast, having the right tools can make all the difference in your ability to produce high-quality, precise, and durable metal parts and structures.

structural steel fabrication hand tools

Angular grinders are commonly seen in metal fabrication and some metal shops. They are types of handheld power tools attached to consumable stone discs or blades. These discs spin at high speed to grind, cut or give a smooth finishing touch to weld metal. Read Also: All about the different types of grinding machines [PDF]. #10 Spark Lighter

2. Incorporate Metal Fabrication Hand Tool Use Into Training. In a small shop environment, especially one where projects change daily and one person may carry parts through multiple steps of fabrication, that person ideally needs to know how to work a hand saw or file just as well as a band saw or deburring machine.We can provide a one-stop-shop for all of your metal fabrication needs. The following is our current list of equipment. Please contact us to learn more about our equipment and specifications, and to request a quote on your next project. Forming. Bystronic XACT Smart 160 Press Brake. 10ft bed; 160-ton capacity; Multi-Axis Backstops; Bi-Soft 7 .This document provides details about a proposed engineering fabrication project, including: 1) The project aims to set up an engineering fabrication unit in Visakhapatnam, India with a total cost of 675 million rupees. 2) The unit will be a proprietorship owned by Smt Ch. Sree Lakshmi and will involve metal fabrication processes like cutting, forming, machining and welding. 3) The .

50LBS Arrow Welding Magnet Holder 4pcs 4" Strong Magnetic Metal Working Mig Tools and Equipment Workshop Welder Magnets Welding Clamps 45, 90, 135 Degree Angle. 4.3 out of 5 stars . 12-Piece Mild Steel Welding Coupons, 14 Gauge Thickness, Welding Practice Kit, Metal Fabrication Training Plates. 4.5 out of 5 stars. 37. 100+ bought in past .The metal fabrication process involves dealing with raw, rough and rugged metal components which are then cut, bent, welded and assembled to form desired metal structures. The main involvement of complex, engaging and intense steps like welding and cutting demands utmost safety precautions if the organization wants to keep their valuable .

-select the most reliable tool for this application Measuring: -ensure the tool is properly calibrated-ensure the tool and the part are clean-perform the measurement in the same manner if repeated measurements are required After measuring: -clean (and oil, if necessary) the tools and store appropriately. 51 It has been practiced for thousands of years and is used to make tools, objects, and structures. 2. Key metalworking techniques include cutting, joining, forming, and casting. Cutting removes material, joining combines pieces, forming reshapes metal without adding or removing material, and casting involves pouring molten metal into molds. 3.SHEET METAL FABRICATION 1. INTRODUCTION: Metal fabrication is the building of metal components and structures by cutting, bending, and assembling processes. . Tools and Ancillaries 1 Misc. equipment Dies tools etc. LS 1 150000 150000 2 Hand Tools and gauges LS 1 50000 50000 Subtotal: 200000required to safely use tools, equipment and materials in the automotive working environment. Evidence requirements It is expected that this evidence will be generated when carrying out practical work and assessments in a workshop. 1. Candidates should list the tools and equipment normally used in the working environment on the job card. 2.

Global Metal Fabrication Equipment Market Size is Anticipated to Exceed USD 103.4 Billion by 2033, Growing at a CAGR of 4.01% from 2023 to 2033. . Metal fabrication equipment refers to the machinery, tools, and equipment used in shaping, cutting, joining, and assembling metal components and structures. . Request Free Sample PDF . 1. Safety Tips For Using Metal Fabrication Tools Three Common Causes of Injuries Improper Tool Usage Workers may suffer injuries due to excessive use, using the wrong tool for the task, inappropriate work area design or insufficient ventilation. Bad Material Handling Procedures Ignoring proper lifting protocols, working longer hours than appropriate and not .advanced QC equipment to further make good on our goal of quality. Page 10 of 13 9200 Ivanhoe Street, Schiller Park, IL 60176 www.ManorTool.com Manor@ ManorTool.com 847-678-2020 . Why Choose Manor Tool for Aerospace Metal Fabrication Services? Since 1959, Manor Tool has been providing professional metal fabrication services, including deep .

MIG welding involves the metal being constantly fed to the joint with the help of a motor. TIG welding produces a much more precision weld thanks to the electric arc and a feeder rod, which is added to the molten metal below to produce a precision weld. Above-mentioned are some of the common tools and equipment used in structural steel fabrication.

2 metal house numbers

metal shaping tools and equipment

$2,195.00

metal fabrication tools and equipment pdf|list of metalworking tools