where sheet metal brackets are used The use of sheet metal in crafting brackets offers excellent durability, versatility, and cost-effectiveness, ensuring robustness in various application scenarios, from mounting . $44.16

0 · sheet metal bracket design guidelines

1 · rectangular metal bracket

2 · metal mounting brackets home depot

3 · metal brackets heavy duty

4 · metal brackets at lowe's

5 · heavy duty steel angle brackets

6 · existing designs for brackets

7 · 2 by four brackets metal

Looking to upgrade your trailer or food truck? Look no further than RecPro's yellow aluminum sheet metal! This 24 gauge sheet is cost-effective, making it perfect for a variety of projects.

Sheet metal brackets are intermediary components used to connect, align, or reinforce objects. They can attach objects together, provide . Sheet metal brackets are used in a wide variety of industries and applications, including: Electrical and electronic areas: Brackets support electrical components, circuit boards, and housings. Automotive field: The bracket can . Copper and copper alloys. Plastic composite. Operation of Fabricating Sheet Metal Brackets. The following are common operations TenRal uses in making sheet metal .

custom metal fabrication winnipeg

The use of sheet metal in crafting brackets offers excellent durability, versatility, and cost-effectiveness, ensuring robustness in various application scenarios, from mounting .A metal bracket is a fastener designed to secure and connect two pieces or objects. They are commonly used to support shelves, stabilize equipment, fasten uprights, or provide decorative accents. Metal brackets can come with or .

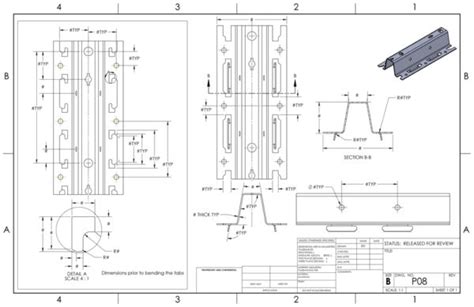

When it comes to sheet-metal brackets, there are several standard styles and shapes. Each sheet metal bracket style serves a specific requirement for mounting a component, or being compatible with a particular surface shape. Sheet metal brackets are components made from sheet metal through cutting, bending, and forming processes designed to support or attach structures. They come in various shapes and sizes, including flat, angle, U, .Desktops, shelving, counter tops, even flooring are held up with a bracket of some type. So you decided to design your own sheet metal part. Use the following simple guidelines to formulate and design the type of sheet metal bracket you .

Whether you need a bracket for your industrial, commercial, or private project, custom metal brackets are essential to fit the dimensions of your space safely and securely. Bespoke metal .Common materials used for custom manufacturing of sheet metal brackets include: Steel: Steel offers high strength and durability, it is very effective for heavy applications. Aluminum: In cases where the application does not involve heavier loads, aluminum can be used which can be an ideal case for weight-related concerns.

What is a bracket? In short, the bracket is an intermediate component used to fix one thing (such as a shelf) to another (such as a wall), and the bracket is connected to other parts with actual fasteners such as screws.Our metal brackets are crafted from high-quality materials to ensure durability and performance. We use Aluminum Alloys (AL5005, AL5052, AL5082, AL6061), Stainless Steel (SUS201, SUS301, SUS304, SUS316, SUS316L), Carbon Steel, Galvanized Steel, Cold Rolled Steel, Copper (Copper 101, Copper C110), and Bronze (Bronze 220, Bronze 510).Metal brackets can be made in various ways, which include casting or CNC machining. However, the ideal way to make brackets is by sheet metal fabrication. One of the processes commonly used for sheet metal fabrication is bending. In this process, a machine called a bend is used to bend sheet metal to an angle up to 120°.Sheet Metal. Part #s Description Fits Price Pictures; D55506 L13218: Used Front Grille/Guard/ Radiator Grille with Grille Retainer Clips: Case 580B: . Used Rear Bracket/Rear Belly Pan Bracket/ Rear Guard Bracket: John Deere 350B 350C 350D: .00 Each Quantity of 2 available as of 6/3/2021 - SC3: T42511 T33460 AR30424

Sheet metal bracket fabrication refers to the process of creating brackets using sheet metal as the primary material. Brackets are essential components used to support, fasten, or position other elements in various structures and equipment.All WITHOUT SELECT-O-SPEED TRANSMISSIONS 1948 to 1964. Front Running Board Bracket right or left side. Price is for EACH bracket. Sheet metal parts may or may not come painted as pictured (unless the description states the color). They often come with only a primer coat of paint. (Item #: 152392, Ref. 8N16470) .00

If we decide to create this sheet metal angle bracket using a press brake, our scope is further narrowed. Most new designers would imagine a part which closely resembles the design pictured (Figure 1). This design is simple, effective, frequently used and rendered with a modern 3D CAD system. The part may look perfect, however, when it is .

Sheet Metal Bending Bracket Maker. A specialized tool designed for efficiently creating custom brackets from sheet metal. It typically features a clamping mechanism and V-shaped dies that allow users to bend sheet metal at precise angles and lengths. These machines are essential for various industries requiring custom bracket solutions.Running Board Bracket - Front - For tractor models 8N, NAA, 600, 601, 700, 800, 801, 900, 2000, 4000. All WITHOUT SELECT-O-SPEED TRANSMISSIONS 1948 to 1964. Front Running Board Bracket right or left side. Price is for EACH bracket. Sheet metal parts may or may not come painted as pictured (unless the description states the color).L brackets The most common bracket type, an L bracket has a single bend that lends it an L shape. L brackets are most often bent at a 90-degree angle but can be bent to angles up to 120 degrees. Z brackets Z brackets have two bends that create parallel flanges pointing in opposite directions, making a Z or double L shape. These brackets are often used to anchor parts at .

The sheet metal passes between the rollers, and the pressure shapes the desired bead profile. The bead roller uses a pair of complementary dies to roll a bead or rib into a sheet metal panel Shrinking and Stretching These two techniques used to change the surface area of sheet metal without significantly altering its thickness.Base metal mountings, fittings and similar articles suitable for furniture, doors, staircases, windows, blinds, coachwork, saddlery, trunks, chests, caskets or the like; base metal hat racks, hat-pegs, brackets and similar fixtures; castors with mountings of base metal; automatic door closers of base metal; and base metal parts thereof: 8302.10Sheet Metal Fabricators Corp. design and fabrication of precision sheet metal bracket components. Primarily, the components we manufacture are used to house various electromechanical controls, making all dimensions critical to assure whole pattern alignment between different parts.

Sheet metal brackets are commonly used in a variety of industries and applications, including automotive, aerospace, construction, and electronics. To learn about Sheet metal design in deep here is a course which can help : Basics of Sheet metal design for Mechanical design engineers. For more content on sheet metal design have a look at the list of articles here : .Automotive Industry Case Study: We produced several metal brackets used in a vehicle’s suspension system in one project. The tolerance for dimensions was +-0.05mm. . What are the common types of tolerances used in sheet metal .

Sheet metal brackets are used extensively in industries and other applications for fixturing and clamping purposes. Holes are commonly drilled in the brackets for weight saving purpose. The size .

Yes, sheet metal brackets can be used outdoors, but the choice of material is crucial for longevity. Stainless steel and aluminum are preferred for their corrosion resistance. A protective finish, such as a powder coating, can further .Sheet metal is a widely used form of raw material, usually 0.006 and 0.25 inches thick sheet used in sheet metal fabrication. Sheet metal electronics are typically constructed from thin metal sheets, such as steel, aluminum, or stainless steel. . Sheet metal brackets and mounts are used to secure and position electronic components within .

The Sheet Metal Bracket market involves the design, manufacturing, and distribution of brackets made from sheet metal, used in various industries such as automotive, aerospace, construction, and .Design Custom Sheet Metal Bracket Principles of Sheet Metal Bracket Design. Two aspects are crucial when designing a metal bracket: its load-bearing capability and aesthetics and functionality. First, we determine the weight the bracket will have to support. You must consider the load and stress placed on it. The selection of material for crafting sheet metal brackets isn’t arbitrary. It’s dictated by a number of factors such as the required strength, the intended use of the bracket, environmental conditions, cost, and even aesthetics. For instance, a bracket meant to support heavy weight might need to be made of a robust material like steel . The kind of metal bracket used for pipe is modern and straightforward. Many pipe brackets are made from metals, including stainless steel, brass, aluminum, and many more. To suit any pipe size, this product comes in various dimensions. . VASUCC Sheet Metal is specialized in sheet metal fabrication including producing quality metal brackets.

I've made lots of small brackets, covers, boxes and frames from 3003 sheet at work. It's very easy to work with and I far prefer it over 6061 for any kind of sheet metal forming work. It's also more corrosion resistant than most aluminum. #10. Strong Bad, Nov 28, 2018 #11. Strong Bad Former World's Foremost Authority.Created by leading bracket manufacturers at Customised Sheet Metal, these heavy-duty brackets can be custom-fabricated to support your industrial, commercial and private projects. With over three decades of experience in the metal fabrication industry, a skilled workforce, and a state-of-the-art computer-controlled precision machinery-equipped .We follow Sheet metal design guidelines to ensure the quality and manufacturability of sheet metal enclosures. As a result, you can deliver the product at a low cost and faster timeline. It is difficult to follow all sheet metal design guidelines for complex sheet metal parts. Therefore exceptions can be there for complex sheet metal parts.

sheet metal bracket design guidelines

Inspiration for a coastal yellow three-story wood house exterior remodel in Houston with a hip roof and a metal roof

where sheet metal brackets are used|2 by four brackets metal