cnc machining for medical imaging Ben Machine provides two crucial roles in CNC machining medical services. Our ability to quickly produce accurate prototypes speeds product development, lowers costs, and improves the final quality.

$16.99

0 · precision of cnc machining

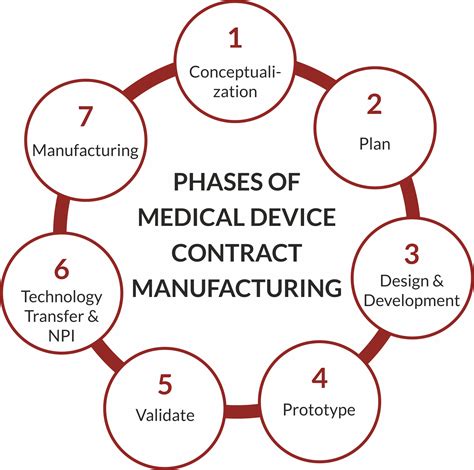

1 · medical machine manufacturing process

2 · medical cnc machining tools

3 · medical cnc machining

4 · medical cnc machine learning

5 · cnc machining accuracy

$19.99

CNC machining is used to produce components and parts for various diagnostic equipment, including imaging systems like MRI and CT scanners, laboratory . CNC machining contributes to the manufacturing of electronic medical equipment by creating durable and precise enclosures, mounts, and connectors. This ensures that devices like pacemakers, monitors, and imaging .CNC machining is employed for rapid prototyping and producing complex medical devices. For example: diagnostic equipment, imaging devices, and monitoring devices. CNC machines are pivotal in the medical device fabrication industry for creating complex, precision parts with excellent repeatability. CNC machining is ideal for manufacturing orthopedic implants, surgical instruments, and the .

Applications and benefits of medical CNC machining vary, and this article will depict how this technology ensures life-saving instruments are fabricated, as well as propels inclusive .Ben Machine provides two crucial roles in CNC machining medical services. Our ability to quickly produce accurate prototypes speeds product development, lowers costs, and improves the final quality.

Medical Imaging Equipment Components: From X-ray tubes to MRI coils, CNC machining is used to create the precise components for these diagnostic tools. Milling, .

In this context, computerized numerical control (CNC) machining has emerged as a crucial technology for medical device manufacturers. This technology allows for the production of complex, highly precise parts with .Medical CNC machining ensures the precision and quality control necessary for creating safe and effective patient devices. Here are key reasons why precision is crucial in CNC machining for . CNC machining is a cost-effective and efficient method for producing highly accurate medical components, eliminating the need for specialized tooling. This process does not involve expensive tooling compared . CNC machining is ideal for manufacturing orthopedic implants, surgical instruments, and the intricate components of medical imaging devices. This fabrication process allows for machining a diverse range of materials .

Through the use of 3D imaging and the latest in computer-aided drafting and design software, we can design parts that can be micro-machined from a variety of different materials, including rigid foam, carving foam, phenolics and . Tight tolerances: CNC machining allows for the manufacturing of additives that meet the extremely tight tolerances wanted for imaging technology. High-satisfactory output: The precision contributes to the general quality and durability of .Cleveland, OH Medical Device Manufacturing: CNC Machining Services. CNC milling and CNC turning are ideal for Cleveland, OH medical device manufacturing thanks largely to: Excellent design precision; Production consistency, from part 1 to part 100,000; Suitability for niche products; Established technology; Wide variety of materials . Medical CNC machining constantly helps engineers and product designers meet the quality and precision demands of the medical industry. Read on for more details. . Magnetic resonance imaging, X-rays, and chemotherapy can all be sources of radioactive contamination in medical parts. The effects of radiation accumulate over a product’s lifetime.

In the realm of medical advancements, CNC machining revolutionize the manufacturing of medical devices with unparalleled precision and reliability. Below you will go into the world of CNC machining for the medical industry, exploring its suitability, methods, materials, applications, advantages, challenges, and guidelines for selecting the best .

Illustration about Advanced cnc machining for medical imaging equipment, showcasing precision and technology, Generated by AI. Illustration of engineering, healthcare, accuracy - 326601883What is Precision CNC Machining of Home Storage Case for Medical Imaging Detectors, CNC Precision Aluminum Parts Processing Non-Standard Hardware Customized Processing Aluminum Plate and Shell Processing manufacturers & suppliers on Video Channel of Made-in-China.com. CNC machining, combined with polishing and coating processes, ensures optimal performance. Medical Imaging Equipment Components: From X-ray tubes to MRI coils, CNC machining is used to create the precise components for these diagnostic tools. Milling, Turning, and grinding are common methods. Precision Computer Numerical Control (CNC) machining is a highly accurate manufacturing methodology that entails the use of computers to manage and control

Nitinol. machining and finishing are some of the final steps on this nickel-titanium alloy’s journey from the earth’s crust into the hands of doctors and bodies of patients as medical devices.. We’ve previously covered how medical nitinol is mined and melted into raw material and then processed into nitinol wires, tubes and sheets for device manufacturers to use in medical . Medical CNC machining is a pivotal aspect of modern healthcare, applying precision engineering to manufacture essential medical components. Through processes like CNC milling and CNC turning, it ensures that tools like CNC medical devices meet the rigorous standards required in the medical field. From cnc machining medical parts to medical device .In short, thermal imaging cameras and CNC machining are very important tools in modern technology, and their application in many fields has become an indispensable part. . Cnc Medical Parts Manufacturing, Precision Medical Parts, robotics part machining, Machining Medical Parts, Medical Precision Machining, All Products. Phone: +8676922689275 CNC machining is a cornerstone in the medical industry, providing bespoke solutions for complex challenges. From intricate surgical instruments to customized prosthetics, the applications are as diverse as they are vital. . By using precise measurements from medical imaging, CNC machines can craft implants and prosthetics that match the exact .

CNC Machining CNC Turning Items for Medical Imaging Parts, Find Details and Price about Machining Custom Precision CNC from CNC Machining CNC Turning Items for Medical Imaging Parts - Dongguan City Longsheng Hardware Technology Co., Ltd. Print This Page.Precision Computer Numerical Control (CNC) machining is a highly accurate manufacturing methodology that entails the use of computers to manage and control עבור לתוכן שירותים

Medical parts have high requirements and harsh material selections and often do not require large batches. Compared with other production processes, CNC machining can better meet the needs of medical .

Myriad Fiber Imaging your finest choice for medical device manufacturing! Contact. 56 Southbridge Road, Dudley MA 01571 + 508 949 3000 Mon-Fri, 7:00 am-5:00 pm Mail us [email protected]. . CNC Machining; Laser Etching; Rapid Prototyping; Additive Manufacturing – 3D Printing; Product Design & Development; Products. Fujikura Image Fiber .

Stone Medical is a Swiss CNC screw machine shop that specialises in medical device manufacturing. Using multi-axis screw machines, we produce high quantity, high complexity products used throughout the medical industry, including bone screws, bone screw extractors, blood transfusion pump shafts, bone anchors and a multitude of other surgical .

Medical CNC machining is highly valuable for creating precise and quality medical parts for various applications. Read on to learn more about this process. . X-rays, magnetic resonance imaging, and chemotherapy are primary radioactive contamination sources in the medical sector. Medical components accumulate the reactions of radiation over .Precision Computer Numerical Control (CNC) machining is a highly accurate manufacturing methodology that entails the use of computers to manage and control. Pāriet uz saturu. Pakalpojumi. CNC apstrāde; CNC virpošana; CNC frēzēšana; 5 asu apstrāde; Precision Machining; CNC urbšana; Kvalitātes kontrole; Vāciņi.

Our team manufacturers an abundance of precision sheet metal parts and CNC machined parts for the medical device industry. We are ISO9001:2015 registered and have extensive experience providing first article reporting, material and process certification requirements and lot traceability. The majority of our experience in the medical industry includes close tolerance sheet metal .

sheet metal workers local 10

As for the Siemens 840Dsl CNC system, this paper investigates the time required for manual programming and SHOPMILL automatic programming, as well as the machining efficiency of these two types of CNC programming based on the cases study of "slot machining workpiece" and "bump milling workpiece" . The experimental results show that for the same .Illustration about Advanced cnc machining for precision component in medical imaging equipment production, Generated by AI. Illustration of equipment, surface, robotic - 324096700 With CNC machining, the medical industry can ensure high-quality patient care and better outcomes for patients. Table of Contents . Pure titanium is radiopaque, making it easy to visualize in medical imaging.Titanium is commonly used in medical instrument machining due to its lightweight, biocompatibility, and corrosion resistance. Orthopedic .Wednesday, September 11, 2024. Home. Business

precision of cnc machining

Illustration about Precision cnc machining for medical imaging equipment advanced technology in action, Generated by AI. Illustration of prototyping, tech, quality - 331015815

medical machine manufacturing process

$417.95

cnc machining for medical imaging|precision of cnc machining