cnc milling processing parts CNC (Computer Numerical Control) milling is a machining process that uses computerized controls to operate and manipulate machine tools that cut and shape materials. . The direction of the grain is an important factor to consider before any sheet metal fabrication process, but especially before bending, folding, and similar deformation processes. This is because grain direction makes sheet .

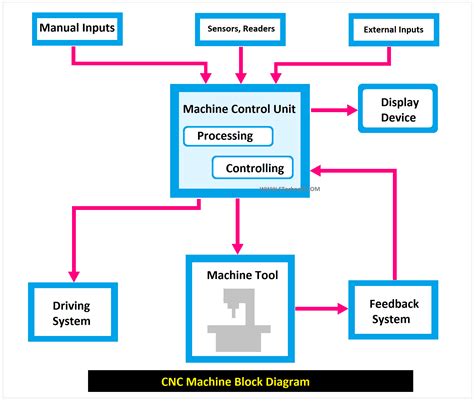

0 · schematic diagram of cnc machine

1 · milling machine parts diagram

2 · homemade cnc parts

3 · cnc milling machine parts names

4 · cnc mill parts diagram

5 · cnc mill diagram

6 · cnc machine parts list pdf

7 · cnc horizontal milling for dummies

Precision Sheet Metal Fabrication helps uphold the highest standards of manufacturing, which inevitably lead to the best outcomes and results. Manages production of replacement parts more efficiently.

CNC (Computer Numerical Control) milling is a machining process that uses computerized controls to operate and manipulate machine tools that cut and shape materials. . CNC milling is the removal of material from a work piece using a combination of special cutting tools and computer programs. A milling machine is used in this process to achieve the desired shape and size of the part with .Xavier is a global precision non-standard parts manufacturer. Its products include CNC machining, five-axis machining, die casting, casting, forging, etc. . Milling, turning and post-processing. Tolerances down to ±0.0008 in(0.020 mm) Lead .

electrical saving box

Learn the basics of CNC milling parts with our comprehensive beginner's guide. Discover how CNC milling works and why it's essential for precision manufacturing. . (Computer Numerical Control) milling is a . Milling machine processing department. CNC lathe. workshop corner. Numerical Control System. Storehouse. workshop corner. Electric Discharge Wire Cutting Machine. . Boosting Efficiency in Parts Processing with CNC Machining 2024-07-01 14:46:36. Discover how CNC machining is revolutionizing parts processing by enhancing precision, increasing .The CNC milling process is suitable to materials like metal, plastic, glass and wood for production of custom parts and custom designed products. There are different types of milling processes done by the CNC milling. . CNC Milling Machine Parts. There are various components of the general CNC milling machine. Let’s see them one by one. 01 .CNC Milling is a widely used manufacturing process that produces CNC parts with precision and accuracy. It is a production process which involves the use of a 3D CAD design, tooling, and machine shop equipment such as heavy duty drill presses and CNC machines to produce a custom 3D CAD model.

CNC Turning Part Supplier, CNC Milling Parts, Sheet Metal Processing Manufacturers/ Suppliers - Xiamen Biaoyuan Precision Hardware Industry Co., Ltd.

“CNC milling for plastic parts has changed the popularity of plastic applications across industries. Think about it: what used to take hours to hand-carve in plastic can now be done in one minute with an accuracy of less than 0.01 millimeters. . CNC Milling and Molding. CNC Milling, a subtractive process, relies on computerized controls to . Our conventional precision metal CNC milling parts is to use lathes, milling machines, drilling machines, polishing and other processes to process various high-precision metal CNC milling parts, such as mechanical keyboard shells and keycaps in the electronics industry, oil cooling and motor shafts in the automotive industry , Model car parts, etc., each .We create CNC machined parts for the automotive industry including powertrain components, suspension components, bushings, valves, and custom performance parts. . 3-axis and 5-axis machining capabilities with years of expertise and ISO9001:2015 and AS9100-certified manufacturing process to create the highest-quality automotive parts on the .

High Precision CNC Processing Stainless Steel Aluminium Parts Precision Machining for Auto Application-Milling Turning Broaching USCNC Turning: Perfect for producing cylindrical parts, our CNC turning services handle a variety of materials and sizes. CNC Milling: Our 3 and 5-axis CNC milling centers allow for complex and precise part production. EDM and Wire EDM: Ideal for intricate and delicate parts, our EDM services ensure precision and fine details..10 -1.00 / Piece 100 Pieces (MOQ) CNC milling is an essential process in the production of complex components. Due to its widespread application, this technology continues to develop and grow. Skip to content. . Most CNC milling parts can achieve high tolerances between+/-0.001 inches and+/-0.005 inches, while some can achieve+/-0.0005 inches. .TenRal’s CNC machine shop features six precision CNC milling machines from Korea, demonstrating the country’s technological prowess in high-end manufacturing. These CNC milling machines are widely used in various industrial production, and can meet the processing needs of different materials and complex shapes.This can include heat treatment, stress relieving, or assembly with other components. Post-processing ensures that the final product meets all the desired specifications and functionality. Step 10: Inspection and Packaging:\ The last step in the CNC machining process involves a final inspection of the finished parts for quality assurance.

It’s main in CNC machining parts, CNC turning parts, CNC milling parts, auto lathe parts, stamping parts. We're a firm-united team of talented and experienced engineers, machinists and technical consultants, who commit to help solve problems relative to manufacturing precision and complex machined parts, including design, product costing .

When you need to manufacture high-precision parts, CNC milling is one of the most commonly used parts processing methods. Modern CNC milling cutters provide huge opportunities for quickly creating free-form .CNC milling is a highly precise and efficient manufacturing process that produces complex and accurate parts. However, despite its precision, CNC milling parts can sometimes experience deformation, resulting in defective parts that do not meet the required specifications. This deformation can occur due to various factors that affect the machining process, such as . 8. For synchronous milling the rotation direction of the milling tool and the feed movement of the work part are parallel. The tooth of the milling cutter immediately penetrates into the work part. Since the milling tool cutting edge is exposed to impact forces the feed drive needs to be play free. Several cutters should always be in operation. The surface quality is flatter and .

CNC milling is a machining process that combines computer numerical control machining systems and a multi-point cutting tool or milling cutter. As one type of CNC machining, it involves mounting the workpiece on a machine bed and cutting materials from a solid block to produce products made of glass, metal, plastic, wood and more specialized materials.

As a customer-oriented company, we provide various CNC machinings services such as CNC turning, CNC milling, wire EDM cutting, swiss machining, and 5-axis machining, which will meet your pluralistic needs as better as possible. Focus on CNC precision hardware parts processing, tolerance down to ± 0.01mm. More. Welcome To QH Technology.Milled parts with on-demand delivery. CNC milling of plastic and metal components. CNC24 means simple procurement processes, on-time delivery and compliance with the highest quality standards. Your milled parts are produced on state-of-the-art 3-axis and 5-axis milling machines. There are hardly any limits to the choice of materials.

Factory Machining CNC Turning High Precision Parts Milling Parts CNC Machining Services. US.80-5.00 / Piece. 100 Pieces (MOQ) . If you are in need of reliable metal sheet processing, CNC machining, stamping parts, or metal deep processing services, Youchun (Hainan) Metal Products Co., Ltd. is your trusted partner. . Benefits of 3-axis CNC Milling. The process is easy to program and can produce parts with simple geometry, with high accuracy; It has high production capacities; . CNC milling can produce parts with very high dimensional accuracy. Tolerances as tight as 0.025 mm are feasible. This high accuracy is crucial to aerospace as well as automotive . CNC milling is a subtractive manufacturing process where material is removed from a solid block to create parts. That being said, there are basic components in every CNC mill that allow it to function as intended. I’ve created a list of the standard and most common CNC milling machine parts that you need to know about. After the parts are finished, they’re unloaded from the CNC milling machine for assembly, consumer delivery, or post-processing. Parts of a CNC Mill. Listed below are the critial components that make up a standard CNC mill: Spindle: The spindle of a CNC mill is designed to spin at a very high rotational speed while withstanding high lateral .

We provide quality custom Cnc Milling services for Cnc Milling parts, cnc milling parts and cnc turning parts at competitive prices with fast delivery and excellent after-sales services. . Because the CNC milling process is the most complex and the technical problems that need to be solved are the most, people have always focused on milling .

electrical rough box with weather seal

schematic diagram of cnc machine

electrical secondary termindation enclosure

milling machine parts diagram

homemade cnc parts

Bending is one of the most common sheet metal fabrication techniques. With bending, metal is deformed with specialist machinery into an angular shape. The bending of sheet metal allows a wide variety of part geometries to be produced and is particularly useful when performed alongside cutting.

cnc milling processing parts|cnc mill diagram