3-axis cnc milling machine pdf Simultaneously, hobbyists, amateurs, and semi-professionals created many solutions for small-scale and low-cost CNC machines. This paper discusses processes for designing and .

Two electric circuits, represented by boxes A and B, are connected as shown in (Figure 1). The reference direction for the current i in the interconnection and the reference polarity for the voltage v across the interconnection are as shown in .

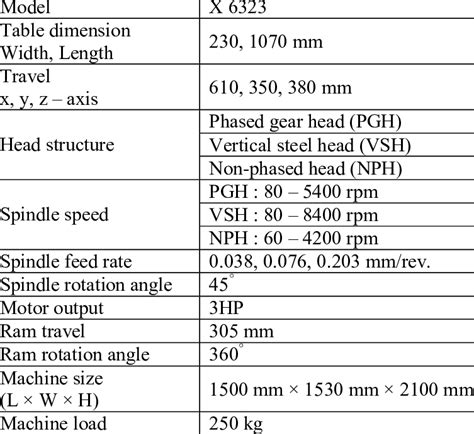

0 · specifications of cnc milling machine

1 · small 3 axis cnc mill

2 · datron cnc price list

3 · axis identification in cnc machine

4 · 3 axis vertical milling machine

5 · 3 axis manual milling machine

6 · 3 axis cnc table

7 · 3 axis cnc machine price

I have an existing junction box and currently 1 source from the basement going in, and one source coming out and that goes to a wall switch. If I want to connect a second wire to come from that junction box, would I just attach all hot and all neutral wires together in the box?

metal gear box 3

specifications of cnc milling machine

This paper discusses processes for designing and developing a PC-based 3-axis CNC milling machine to meet small-scale and cost-effective machine manufacturing .© 2008-2024 ResearchGate GmbH. All rights reserved. Terms; Privacy; IP .The study’s main objective is to propose a process for designing and .

small 3 axis cnc mill

In this paper we describe the development and validation of software and hardware .

The study’s main objective is to propose a process for designing and manufacturing a mini vertical 3-axis CNC milling machine with low cost but full features similar to an industrial.Simultaneously, hobbyists, amateurs, and semi-professionals created many solutions for small-scale and low-cost CNC machines. This paper discusses processes for designing and .

In this paper we describe the development and validation of software and hardware that allows the user to command a CNC gantry milling .This paper discusses the development of a low cost CNC milling machine components which is capable of 3-axis simultaneous interpolated operation. .

paper will present the design and fabrication of 3-axis milling machine. computer numerically-controlled (CNC) machine which comprise the use of Arduino micro controller to produce pulse .The purpose of this article is to design and build a 3-axis CNC milling machine with a PC-based micro CNC milling machine that performs machining using G-code. This machine is not . This paper discusses processes for designing and developing a PC-based 3-axis CNC milling machine to meet small-scale and cost-effective machine manufacturing requirements. The study’s main objective is to propose a process for designing and manufacturing a mini vertical 3-axis CNC milling machine with low cost but full features similar to an industrial.

Simultaneously, hobbyists, amateurs, and semi-professionals created many solutions for small-scale and low-cost CNC machines. This paper discusses processes for designing and developing a PC-based 3-axis CNC milling machine to meet small-scale and cost-effective machine manufacturing requirements. In this paper we describe the development and validation of software and hardware that allows the user to command a CNC gantry milling machine so that it will machine parts using the.This paper discusses the development of a low cost CNC milling machine components which is capable of 3-axis simultaneous interpolated operation. The lower cost is achieved by incorporating the features of a standard PC interface with micro-controller based CNC system in an Arduino based embedded system.paper will present the design and fabrication of 3-axis milling machine. computer numerically-controlled (CNC) machine which comprise the use of Arduino micro controller to produce pulse-width modulation (PWM) outputs in order to run the stepper motors that will be used in this work.

The purpose of this article is to design and build a 3-axis CNC milling machine with a PC-based micro CNC milling machine that performs machining using G-code. This machine is not suitable for production and precision machining.Simulation and Optimization of 3 Axis CNC Milling Machine Structure. ABSTRACT: The thorough design and modeling of a 3-axis Numerical Control (NC) machine tool utilizing Solid-works, a well-known Computer-Aided Design (CAD) program, are presented in this work.The motor mounting was machined with a three-axis CNC milling machine. The bearing mounted pulley shafts were manufactured on a manual flat bed lathe. The motor to pulley coupling is achieved with poly-vinyl tubing. A 400 count per revolution optical encoder is used to .Collecting the information of the necessity of milling and drilling machine. Gathering the data from literature review. Study of existing machine and focus on various modification. Identifying the proper mechanism and their role. Verify the design of PCB milling and drilling machine.

This paper discusses processes for designing and developing a PC-based 3-axis CNC milling machine to meet small-scale and cost-effective machine manufacturing requirements.

The study’s main objective is to propose a process for designing and manufacturing a mini vertical 3-axis CNC milling machine with low cost but full features similar to an industrial.Simultaneously, hobbyists, amateurs, and semi-professionals created many solutions for small-scale and low-cost CNC machines. This paper discusses processes for designing and developing a PC-based 3-axis CNC milling machine to meet small-scale and cost-effective machine manufacturing requirements.

In this paper we describe the development and validation of software and hardware that allows the user to command a CNC gantry milling machine so that it will machine parts using the.This paper discusses the development of a low cost CNC milling machine components which is capable of 3-axis simultaneous interpolated operation. The lower cost is achieved by incorporating the features of a standard PC interface with micro-controller based CNC system in an Arduino based embedded system.paper will present the design and fabrication of 3-axis milling machine. computer numerically-controlled (CNC) machine which comprise the use of Arduino micro controller to produce pulse-width modulation (PWM) outputs in order to run the stepper motors that will be used in this work.The purpose of this article is to design and build a 3-axis CNC milling machine with a PC-based micro CNC milling machine that performs machining using G-code. This machine is not suitable for production and precision machining.

Simulation and Optimization of 3 Axis CNC Milling Machine Structure. ABSTRACT: The thorough design and modeling of a 3-axis Numerical Control (NC) machine tool utilizing Solid-works, a well-known Computer-Aided Design (CAD) program, are presented in this work.The motor mounting was machined with a three-axis CNC milling machine. The bearing mounted pulley shafts were manufactured on a manual flat bed lathe. The motor to pulley coupling is achieved with poly-vinyl tubing. A 400 count per revolution optical encoder is used to .

datron cnc price list

axis identification in cnc machine

metal gear rex cardboard box

metal gear rising revengeance black box trainer

The Hammond 1414 N4 series of mild steel junction boxes can be .

3-axis cnc milling machine pdf|axis identification in cnc machine