cnc machine atc An automatic tool changer improves the production and tool-carrying capacity of a CNC machine by changing tools very quickly without the help of a manual operator. In doing so, the ATC dramatically reduces .

The following are the main welding processes used for Sheet Metal welding: Stick Welding or SMAW; Gas Tungsten Arc Welding (GTAW or TIG)

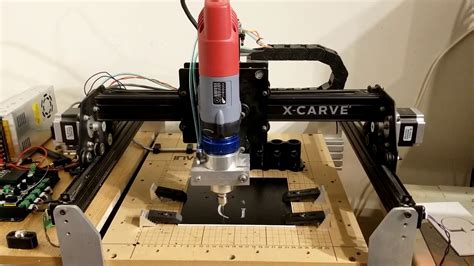

0 · types of atc in cnc

1 · tool changer for cnc router

2 · hobby cnc tool changer

3 · disadvantages of automatic tool changer

4 · desktop cnc with atc

5 · cnc with automatic tool changer

6 · best atc cnc machine

7 · automatic bit changer for cnc

Learn why MIG, pulsed MIG, TIG and pulsed TIG are the ideal choices when welding sheet metal. When welding thin metal, the main objective is to avoid warping, burn .

Stop cutting corners and produce quality, finished parts with ease. Stop watching your machine sit idle while you hunt for wrenches and change tools by hand. Your time is valuable, and so is your machine’s. Machine better .In machining, an automatic tool changer (ATC) is used in computerized numerical control (CNC) machine tools to improve the production and tool carrying capacity of the machine. ATCs change tools rapidly, reducing non-productive time. They are generally used to improve the capacity of the machines to work with a number of tools. They are also used to change worn out or broken tools. They are one more step towards complete automation.

With an advanced handheld control allowing tool path previewing, a 5-position automatic tool changer, and a vacuum table, the Laguna iQ Pro with ATC presents an elevated performance .

metal fabricators in camden nj

Need to upgrade your ordinary CNC routers with automatic tool changer kits? Review 2024 best ATC CNC router machines with expert reviews for starters . With an ATC, a CNC machine becomes more autonomous and can work for longer production runs without interruption. In this post, we’ll go over the purpose of an automatic tool changer in CNC machining and how you can . An automatic tool changer improves the production and tool-carrying capacity of a CNC machine by changing tools very quickly without the help of a manual operator. In doing so, the ATC dramatically reduces .The ShopBot Desktop MAX ATC takes the precision and reliability of our Desktop MAX CNC and accelerates your machining process with the addition of a 7-tool automatic changer.

Our ATC Systems include all the components necessary to have a fully functional ATC on your hobby or semi-pro CNC machine. ATC Motor in either 1.5kw 110v or 2.2kw 220v both are water-cooled 80mm capable of holding ISO20/ER20 tool .

types of atc in cnc

Automatic Tool Changer (ATC) is a feature in CNC machines that enables the automatic change of cutting tools without the need for operator intervention. The ATC system consists of a magazine that holds a variety of . Stop cutting corners and produce quality, finished parts with ease. Stop watching your machine sit idle while you hunt for wrenches and change tools by hand. Your time is valuable, and so is your machine’s. Machine better parts, in less time, with less effort. Invest in your machine today!

In machining, an automatic tool changer (ATC) is used in computerized numerical control (CNC) machine tools to improve the production and tool carrying capacity of the machine. ATCs change tools rapidly, reducing non-productive time.Read this article to gain a comprehensive understanding of automatic tool changers and their common types. We’ll dive into the world of ATCs, explaining their purpose, benefits, and four popular types widely used in the industry.

With an advanced handheld control allowing tool path previewing, a 5-position automatic tool changer, and a vacuum table, the Laguna iQ Pro with ATC presents an elevated performance of one of our best-selling CNCs.

Need to upgrade your ordinary CNC routers with automatic tool changer kits? Review 2024 best ATC CNC router machines with expert reviews for starters and pros. With an ATC, a CNC machine becomes more autonomous and can work for longer production runs without interruption. In this post, we’ll go over the purpose of an automatic tool changer in CNC machining and how you can benefit from using one.

An automatic tool changer improves the production and tool-carrying capacity of a CNC machine by changing tools very quickly without the help of a manual operator. In doing so, the ATC dramatically reduces downtime on a given project.

The ShopBot Desktop MAX ATC takes the precision and reliability of our Desktop MAX CNC and accelerates your machining process with the addition of a 7-tool automatic changer.Our ATC Systems include all the components necessary to have a fully functional ATC on your hobby or semi-pro CNC machine. ATC Motor in either 1.5kw 110v or 2.2kw 220v both are water-cooled 80mm capable of holding ISO20/ER20 tool holders Automatic Tool Changer (ATC) is a feature in CNC machines that enables the automatic change of cutting tools without the need for operator intervention. The ATC system consists of a magazine that holds a variety of tools, a tool changing mechanism, and a controller that manages the tool changes.

Stop cutting corners and produce quality, finished parts with ease. Stop watching your machine sit idle while you hunt for wrenches and change tools by hand. Your time is valuable, and so is your machine’s. Machine better parts, in less time, with less effort. Invest in your machine today!In machining, an automatic tool changer (ATC) is used in computerized numerical control (CNC) machine tools to improve the production and tool carrying capacity of the machine. ATCs change tools rapidly, reducing non-productive time.

metal fabricators denver

Read this article to gain a comprehensive understanding of automatic tool changers and their common types. We’ll dive into the world of ATCs, explaining their purpose, benefits, and four popular types widely used in the industry.With an advanced handheld control allowing tool path previewing, a 5-position automatic tool changer, and a vacuum table, the Laguna iQ Pro with ATC presents an elevated performance of one of our best-selling CNCs.Need to upgrade your ordinary CNC routers with automatic tool changer kits? Review 2024 best ATC CNC router machines with expert reviews for starters and pros. With an ATC, a CNC machine becomes more autonomous and can work for longer production runs without interruption. In this post, we’ll go over the purpose of an automatic tool changer in CNC machining and how you can benefit from using one.

An automatic tool changer improves the production and tool-carrying capacity of a CNC machine by changing tools very quickly without the help of a manual operator. In doing so, the ATC dramatically reduces downtime on a given project.The ShopBot Desktop MAX ATC takes the precision and reliability of our Desktop MAX CNC and accelerates your machining process with the addition of a 7-tool automatic changer.

tool changer for cnc router

hobby cnc tool changer

Our ATC Systems include all the components necessary to have a fully functional ATC on your hobby or semi-pro CNC machine. ATC Motor in either 1.5kw 110v or 2.2kw 220v both are water-cooled 80mm capable of holding ISO20/ER20 tool holders

metal fabricators in alabama

disadvantages of automatic tool changer

Follow these steps to build a quality metal cabinet: Cut metal stud framing to size according to your plan using an electric saw or hacksaw. Wear eye and hand protection. Connect the studs together into a rectangle with self-tapping metal screws. If needed, weld angle brackets onto the frame to increase strength. Paint the frame if desired.

cnc machine atc|automatic bit changer for cnc